Industrial Cable Manufacturer

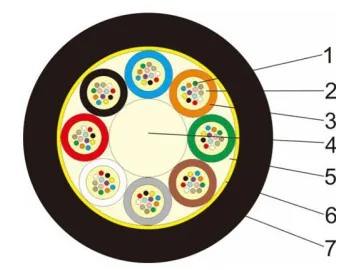

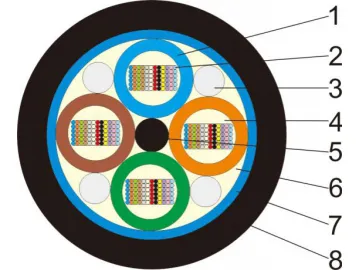

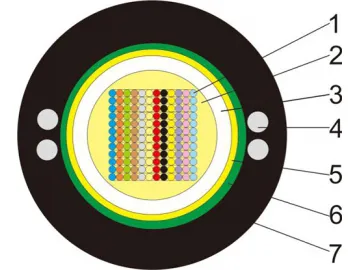

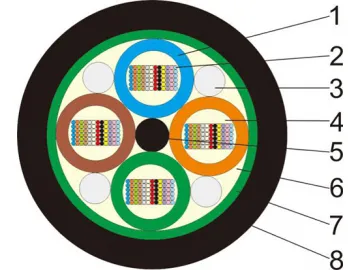

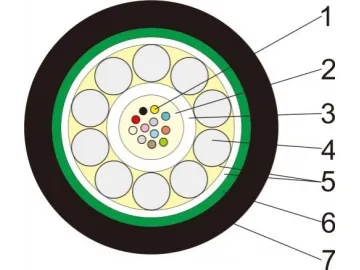

The long distance optical fiber composite cable usually adopts an all-dielectric form, which means the strength member is nonmetallic.

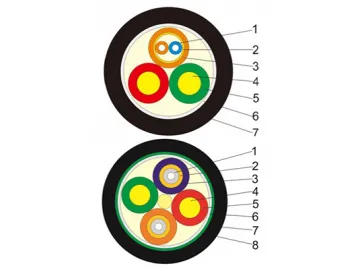

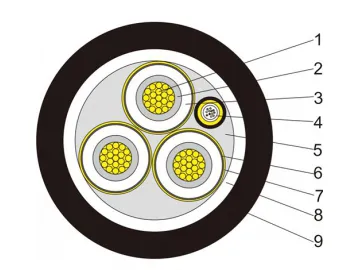

The BBU+RRU remote base station requires fewer cores of fiber optic cable, so it is more flexible for combination. Its opto-electronic hybrid structure can be used in some individual applications.

As to the design of the structure, the long distance optical fiber composite cable adopts tight-buffered optical fiber to reduce its diameter and further increase its tensile strength and side-pressure resistance performance. It is convenient to connect the end of optical fiber with connectors.

We use aramid yarn to fabricate the strength member to promote the drawing force for short term and toughness of optical cable.

Considering the various indoors service conditions, we adopt LZSH materials to fabricate its sheath.

Parameter 1. Technical parameter| Item | Content | Value | |||

| Number of cores | 2 | 4 | 8 | 12 | |

| Reference outer diameter | mm | 11.5 | 15.0 | 25.0 | 33.0 |

| Tight-buffered optical fiber | Material | LSZH | |||

| Outer diameter /mm | (0.6/0.9)±0.05 | ||||

| Strength member | Material | aramid yarn | |||

| Loose tube | Outer diameter/mm | 2.0±0.1 | |||

| Thickness/mm | ≥0.3 | ||||

| Direct-current resistance of single conductor | (Ω/100m) | 13.3 | |||

| Feeder line | Sectional area of conductor /mm² | 1.5 | |||

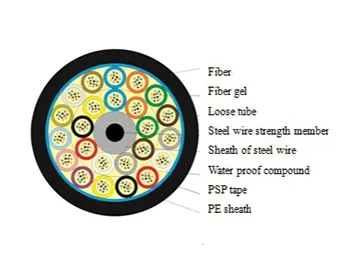

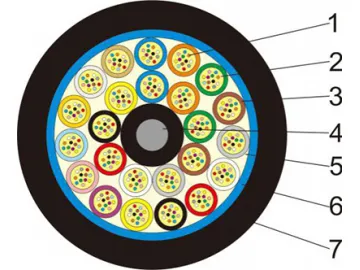

| Central strength member | Material | FRP | |||

| Tape layer | Material | Polyester tape, non-woven polyester tape, water blocking tape, etc. | |||

| Outer sheath | Material | LSZH/PVC/TPU/PE | |||

| Range of operating temperature | ℃ | -40 ~ +70 | |||

| Tensile force | Short term/long term / N | 1000/500 | |||

| Flattening | Short term/long term / N | 2000/1000 | |||

| * The color and color spectrum of fiber optics are formulated according to identification tables. * We can change the quantity of fiber optic and specification of feeder line according to customers' requirement. * The outer diameter and weight of optical cable are typical values, and they will change in different structures. | |||||

| G.652.D | G.657A2 | 50/125μm | 62.5/125μm | ||

| Attenuation | @850nm | - | - | ≤3.0dB/km | ≤3.0dB/km |

| @1300nm | - | - | ≤1.0dB/km | ≤1.0dB/km | |

| @1310nm | ≤0.36dB/km | ≤0.36dB/km | - | - | |

| @1550nm | ≤0.22dB/km | ≤0.23dB/km | - | - | |

| Bandwidth | @850nm | - | - | ≥500MHz·km | ≥200MHz·km |

| @1300nm | - | - | ≥1000MHz·km | ≥600MHz·km | |

| Fiber cutoff wavelength | ≤1260nm | ≤1260nm | - | - | |

| Polarization mode dispersion | Single optical fiber | ≤0.20ps/√km | ≤0.20ps/√km | - | - |

| Link value(M=20, Q=0.01%) | ≤0.10ps/√km | ≤0.10ps/√km | - | - | |

| Item | Inspection standard | Specified value | Requirements |

| Pull | IEC 60811-1-1 | According to technical parameter | Additional attenuation≤0.03dB |

| Flatten | IEC 60811-1-1 | According to technical parameter | Additional attenuation≤0.03dB |

| Backward and forward bending | IEC 60811-1-1 | Load: 40N 15 times | Additional attenuation: single-mode≤0.4dB; multi-mode≤0.6dB |

| Twisting | IEC 60811-1-1 | Load: 40N 10times | Additional attenuation: single-mode≤0.4dB; multi-mode≤0.6dB |

| temperature recycle test | IEC 60794-1-2-F1 | -40℃ ~+70℃ | Additional attenuation: single-mode≤0.5dB; multi-mode≤0.3dB |

| voltage test | IEC 60227-1 | applied voltage: DC2.5Kv, 5min | Every single wire will not be broken down after being shield with other core wires. |

| insulation resistance | IEC 60227-1 | +20℃, DC 500v, 1min | The insulation resistance of the single wire, being shield with other core wires: ≥10MΩ*km |

| Combustion performance | IEC 60332-1-2 | Fire resistance | Every single wire can be burnt vertically. |

| Density of the smoke | Light transmittance ≥50% | ||

| Corrosiveness | PH of the gas when burning≤4.3; electric conductivity≤10μs/mm | ||

| * The monitoring of all optical fiber attenuation's change is operated in wavelength of 1550nm. | |||

This product has the advantages of convenient installation, energy conservation and environment protection. The power supply comes from machine room, which is segregated with alternating current. The stable power supply will effectively eradicate power cutoff accidents. This product can realize the automatic disconnection of short circuit, shut off to reduce the risks of electric leakage.

Links:https://www.globefindpro.com/products/50025.html

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

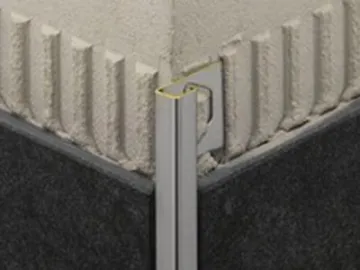

Tile Trim

Tile Trim

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Glass Block / Glass Brick

Glass Block / Glass Brick

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer