Benchtop Vision Guided 3-Axis Dispensing Robot

The benchtop vision guided 3-axis dispensing robot is a high precision dispensing robot & jet dispenser that is at the top of the industry in terms of performance, usability, reliability and other aspects. It meets all customer requirements for both production efficiency and process quality.

The machine is used in the production of, or processes involving the following products:

CCM

VCM

Flat motor

Linear motor

Fingerprint identification

FPC flexible printed circuit

Integrated circuit

Integrated circuit under fill

Micro electrical machine system

Organic light-emitting diode, OLED

Features

1. High-performance

This equipment uses a servo motor and lapping leading screw module to ensure high accuracy, high speed, high efficiency, and high consistency of the system.

The repeatable positioning accuracy of the platform reaches 0.01mm. The platform is equipped with an independent core pneumatic controller or jetting valve to achieve a highly precise, stable discharge of fluid and precise control of trajectory.

The non-contact mode can achieve the stability of 0.25mm glue line width or dot diameter.

2. Intelligent design

A variety of intelligent modules such as intelligent identification, laser altimetry, automatic needle correction, on-line UV exposure, liquid-level detection are available

3. Special functions

It has a unique dispensing process module. Air-blowing and air-inhalation are two ways to automatically clean the glue valve, which effectively prevents glue hanging.

Parameters

| Model | VS-300 | |

| Structure | Rectangular coordinates type | |

| Axis No. | 3 | |

| Max acceleration X/Y/Z (g) | 1g/1g/0.5 | |

| Motion range X/Y/Z (mm) | 300/300/100 | |

| Speed Range (m/s) | X/Y | 1000 |

| Z | 500 | |

| Repositioning accuracy (mm) | X/Y/Z | ±0.025 |

| Resolution (mm) | X | 0.004 |

| Y | ||

| Z | ||

| Loading-plate load(kg) | 10 | |

| Z axis load(kg) | 5 | |

| Power (W) | 450 | |

| Driving type | AC servo | |

| Transmission type | Lead screw | |

| Programming type | Based on PC development | |

| Camera pixel | 1.3M pixel | |

| Light source | LED (blue or red) | |

| Weight (kg) | 76 | |

| Dimension (L*W*H) | 576×514×626 | |

| Input voltage | 220V AC 50Hz | |

| Work environment | Temperature 0-40℃, Humidity 20-90% (No condensation) | |

Three-axis platform

Red and blue visual module

Dispensing process module

Optical equipment

Laser height sensor

Height calibration module

On-line UV curing module

Pneumatic jetting valve (common configuration, hot melt adhesive configuration HM, anaerobic adhesive configuration AA)

Piezoelectric jetting valve (common configuration, hot melt adhesive configuration HM, anaerobic adhesive configuration AA)

Pneumatic stabilization module

Pneumatic alarm module

Liquid level measurement

Related

industrial robot, glue dispenser, liquid dispersing

Links:https://www.globefindpro.com/products/50327.html

-

Inflatable Life Raft

Inflatable Life Raft

-

6.2m Rigid Hull Inflatable Boat RIB

6.2m Rigid Hull Inflatable Boat RIB

-

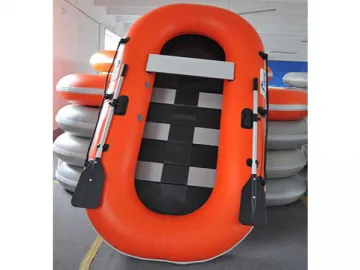

6 Person Inflatable Boat

6 Person Inflatable Boat

-

3.8m Rigid Hull Inflatable Boat RIB

3.8m Rigid Hull Inflatable Boat RIB

-

Dispensing Robot / Jet Dispenser Core Components

Dispensing Robot / Jet Dispenser Core Components

-

Heavy Duty Disc Springs

Heavy Duty Disc Springs

-

Inflatable Fishing Boat

Inflatable Fishing Boat

-

6.6m Rigid Hull Inflatable Boat RIB

6.6m Rigid Hull Inflatable Boat RIB

-

8 Person Inflatable Boat

8 Person Inflatable Boat

-

Luxury RIB 520 (Rigid Inflatable Boat)

Luxury RIB 520 (Rigid Inflatable Boat)

-

5m Fishing Boat

5m Fishing Boat

-

2.4m-4.8m Open Deck Aluminum Hull RIB Boat

2.4m-4.8m Open Deck Aluminum Hull RIB Boat