Dispensing Robot / Jet Dispenser Core Components

Mingseal provides core components for dispensing robot/jet dispenser for purchasers, including piezoelectric jetting valve, piezoelectric jetting controller, temperature controller and heater and more.

Applicable products and processes

Wafer level packaging

Advanced Camera Module (CCM)

Under fill process for flip chip (FC)

Under fill process for high density printed circuit board (PCB) Under fill process for ball grid array (BGA) and chip scale package (CSP)

Under fill process for package on package (POP)

Micro-speaker and micro-receiver

Voice coil motor and vibration motor

Corner and edge connection

Dam and fill process

SMT adhesive dispensing

Conductive epoxy resin

Standard configuration

PJV-100-U runner

PJV-100 piezoelectric jetting valve

PJC-100 piezoelectric jetting controller

Optical configuration

PJV-100-Y anaerobic adhesive with channel

PJV-100-R hot melt adhesive with channel

HM-310 heater

HM-320 barrel controller

HC-570A temperature controller

HC-570B temperature controller

Piezoelectric jetting valve

Piezoelectric jetting valves use micro-jet dispensing technology, allowing them to be used in It advanced semiconductor manufacturing and mobile electronic equipment packaging and other fields of non-contact dispensing operations. The jetting valve is also suitable for various types of fluid jets, such as solder paste, silver paste, hot melt glue, anaerobic adhesive, red glue, UV glue and hydrogel, and works with a glue dispenser or automatic line. Not only can it achieve a high speed continuous long line production, but it also lowers usage costs.

It features a special structure and control design. The minimum dot diameter is 0.2mm. Dispensing processes are carried out in a narrow slot of 0.1mm.

The minimum shot volume is less than 0.5nl.

Parameter adjustment is easy and convenient, it can be quantified and features a wide range of applications.

It is suitable for various kinds of dispensing systems.

It adopts a modular design. Users need only to replace or add the corresponding modules to achieve a special glue jetting such as anaerobic adhesive and hot melt glue.

It can efficiently lower user consumables and usage costs.

Specifications

| Model | PJV-100 PJV piezoelectric jetting valve |

| Feeding pressure range (Bar) | 0.1~8 |

| Dispensing material's viscosity (mpas) | Middle or high viscosity, up to 200 000 |

| Max jetting frequency (Hz) | 1000 |

| Corrosion resistance | All water medium, organic solvents, weak acid and weak base |

| Weight. (g) | 240 |

| Dimension L*W*H (mm) | 100×40×12 |

| Work temperature range(°C) | 10~50 |

Piezoelectric jetting controller

| Model | PJC-100 piezoelectric jetting controller |

| Pulse parameters and accuracy (mm) | 0.01ms~1000.00 |

| Accuracy(ms) | 0.01 |

| Dispensing frequency | 1~1000HZ |

| Parameters and setting display | TFT color screen |

| Parameter memory | 10 |

| Reserved port | 2-way serial communication interfaces and 8-way I/O |

| Weight. (g) | 1500 |

| Dimension L*W*H (mm) | 280×92×185 |

| AC current input | 100~240V AC |

Temperature controller

| Model | HC-570A/HC-570B temperature controller |

| Temperature control accuracy (°C) | ±2 |

| Temperature heating range (°C) | Normal temperature ~200 |

| Weight. (g) | 500 |

| Dimension L*W*H (mm) | 140×92×185 |

| AC current input | 220V±20% AC |

Other components

Heater

Barrel heater Related

industrial robot parts, liquid dispersing, adhesive dispensing

Links:https://www.globefindpro.com/products/50334.html

-

Heavy Duty Disc Springs

Heavy Duty Disc Springs

-

D3240 24V 10mm Flexible LED Light Strip

D3240 24V 10mm Flexible LED Light Strip

-

D6120H 24V 8mm Ceiling LED Strip Light

D6120H 24V 8mm Ceiling LED Strip Light

-

SN-V24-100S 24VDC 100W LED Power Supply

SN-V24-100S 24VDC 100W LED Power Supply

-

D4240 24V 15mm Under Cabinet Lighting LED Strip

D4240 24V 15mm Under Cabinet Lighting LED Strip

-

CM2-C1D-A1 LED Dimmer, LED Controller

CM2-C1D-A1 LED Dimmer, LED Controller

-

3.8m Rigid Hull Inflatable Boat RIB

3.8m Rigid Hull Inflatable Boat RIB

-

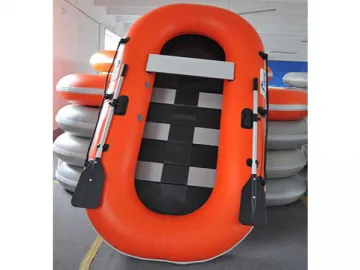

6 Person Inflatable Boat

6 Person Inflatable Boat

-

6.2m Rigid Hull Inflatable Boat RIB

6.2m Rigid Hull Inflatable Boat RIB

-

Inflatable Life Raft

Inflatable Life Raft

-

Benchtop Vision Guided 3-Axis Dispensing Robot

Benchtop Vision Guided 3-Axis Dispensing Robot

-

Inflatable Fishing Boat

Inflatable Fishing Boat