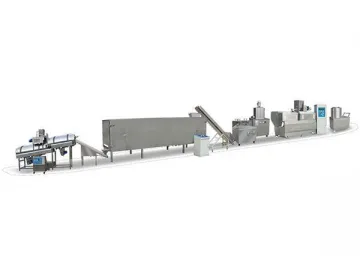

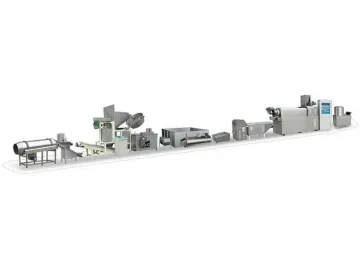

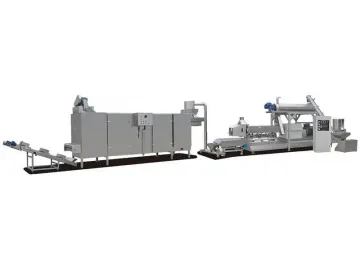

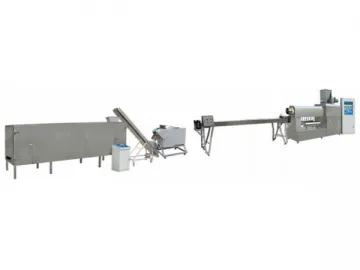

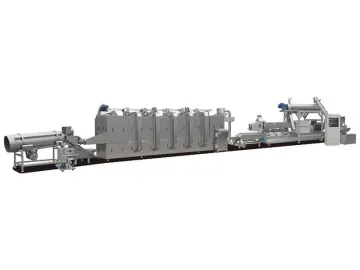

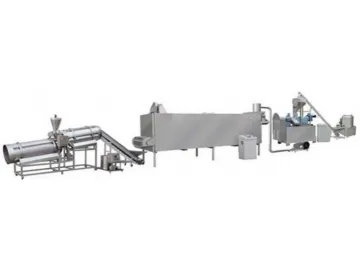

Filled Snack Processing Equipment (multigrain cracker, rice cracker)

Introduction

The filled snack processing equipment (multigrain cracker, rice cracker) introduced by Luerya features highly advanced extrusion technology. It can reduce the workload of the operator by changing the mold and the production process automatically.

The equipment is used to produce popular filled snacks like wheat crackers, rice cracker and so on.

Characteristics

The equipment only takes floor space 200m2.

The equipment has flexible configuration which can be adjusted according to customers’ needs. And all those devices can be placed at 90 degrees.

Equipment flowsheet

Flour mixer → Food process extruder with twin screw → Filler machine → Multifunction shaper → Big elevator → Three-layer electric oven → Automatic seasoning line

Equipment layout and technical parameters

| Name | Production Line Configuration | Throughput | Power Consumption | Dimension |

| Filled snack | 1. Mixing machine 2. Food process extruder with twin screw 3. Plastic cutting machine 4. Filling machine 5. Lifting machine 6. Oven 7. Automatic seasoning line | 100-120kg/h | 55KW | 18x0.8x1.6m |

| Burned wheat food | 1. Mixing machine 2. Food process extruder with twin screw 3. Plastic cutting machine 4. Filling machine5. Lifting machine 6. Spreader7. Oil injecting machine 8. Candy melting and spray machine 9. Spreader 10. Oven 11. Cooler | 100-120kg/h | 75KW | 30x0.8x2.0m |

| Crispy rice food | 1. Mixing machine2. Food process extruder with twin screw 3. Plastic cutting machine4. Automatic fryer 5. Octagonal roller | 120-180kg/h | 80KW | 24x0.8x2.0m |

| Snack food | 1. Mixing machine 2. Food process extruder with twin screw 3. Blower 4. Oven 5. Automatic seasoning machine | 120-150kg/h | 68KW | 24x0.8x2.0m |

Extruded Snack Food by Filled snack processing equipment

Index

food processing equipment, commercial food machines, food manufacturing line, puffed food machines

Scan QR to Read

Links:https://www.globefindpro.com/products/50476.html

Links:https://www.globefindpro.com/products/50476.html

Recommended Products

-

Bread Crumb Processing Machine Line

Bread Crumb Processing Machine Line

-

LG4747 Corner Neon Light Fixture

LG4747 Corner Neon Light Fixture

-

Potato Chips, French Fries Processing Line

Potato Chips, French Fries Processing Line

-

Crispy Snack Manufacturing Line (mixer, extruder, deep fryer, seasoning, coating)

Crispy Snack Manufacturing Line (mixer, extruder, deep fryer, seasoning, coating)

-

Screw Shell Food Processing Equipment Line

Screw Shell Food Processing Equipment Line

-

Protein Food Processing Line

Protein Food Processing Line

-

Automatic Instant Noodle Production Line

Automatic Instant Noodle Production Line

-

Commercial Deep Fryer

Commercial Deep Fryer

-

Pet Chewing Food Manufacturing Equipment

Pet Chewing Food Manufacturing Equipment

-

Vertical Form Fill Seal Machine

Vertical Form Fill Seal Machine

-

Pet Food Processing Equipment

Pet Food Processing Equipment

-

Corn Stick Snack Manufacturing Machine Line

Corn Stick Snack Manufacturing Machine Line

Hot Products