Single Stage Screw Compressor

Optimized structure design

The single stage screw compressor has compact structure. The optimized structure design ensures low noise, and low vibration.

High precision oil separating efficiency

The unit has high oil separation efficiency up to 10PPM, due to its adoption of multiple types of oil separation methods, such as four-times of impaction, the separation of large-diameter particles from the liquid by gravity method, highly efficient molecular material filtration, and more.

Highly efficient oil cooling unit

The device adopts a highly efficient heat exchange tube with small size. Both thermosiphon cooling and water cooling methods are available.

Low resistance, high-precision oil filter

An oil filter made of WU-type high-performance stainless steel wire mesh is adopted. This ensures high filtration precision and low oil path resistance.

Efficient direct connection between motor and compressor

The screw compressor is connected with the bipolar motor via a diaphragm coupling, and offers high speed, good auto-centering capability, and long service life.

Optimized oil way design

International advanced oil way design decreases the oil mass required for force feed lubrication system, reduces the oil pump displacement and shaft power, and overcomes the unstable oil pressure problem caused by varied working conditions.

Improved efficiency due to the design of economizer

The compression cycle with an economizer allows the screw type refrigeration compressor to operate economically at low temperature running conditions.

Applications

Our single stage screw compressor can be found in variety of industries, such as the refrigeration, food processing, vacuum drying, pharmacy, chemical, and more fields.

Links:https://www.globefindpro.com/products/51231.html

-

Saltwater Block Ice Machine

Saltwater Block Ice Machine

-

Exposed Thermostatic Shower Valve, HL7025

Exposed Thermostatic Shower Valve, HL7025

-

Concrete Cooling

Concrete Cooling

-

Exposed Basin Mixer, FL7080

Exposed Basin Mixer, FL7080

-

Containerized Water Chiller

Containerized Water Chiller

-

Flake Ice Machine On Board

Flake Ice Machine On Board

-

Right Angle Speed Reducer

Right Angle Speed Reducer

-

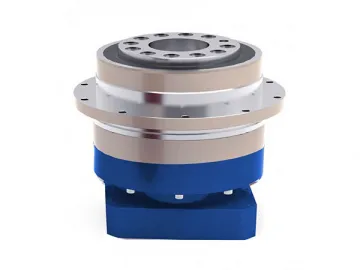

PAD Flange Mount Speed Reducer

PAD Flange Mount Speed Reducer

-

SEC Evaporative Condenser

SEC Evaporative Condenser

-

Pneumatic Ice Weigher

Pneumatic Ice Weigher

-

Plate Freezer

Plate Freezer

-

Air Ice Delivery System

Air Ice Delivery System