Solid Waste Pyrolysis Furnace

The solid waste pyrolysis furnace is mainly used for pyrolysis of organic solid waste. The design of the key device, pyroysis furnace, adopts manufacturing standard of pressure vessel, thus solving the problem that the vertical furnace will break easily because of the uneven heating of the bottom.

Parameters| Model | Material | Dimension | Temperature(℃) | Weight(kg) | Volume m³ | Heat exchange area (m3) |

| YT-LJ-30 | Q345R | 7325*3100*3640 | 500 | 24855 | 30 | 17 |

Features

Advanced technique

The solid waste pyrolysis furnace adopts advanced separation-free technology that there is no need to separate the rubber and steel wire before pyrolysis, thus reducing the energy consumption and greatly improving economic benefit.

Micro negative pressure system

The pyrolysis furnace adopts unique micro negative pressure technique to prevent gas leakage during production, thus greatly improving the pyrolysis efficiency. And this can fundamentally eliminate safety concerns caused by gas leakage.

Reduced pollution

It adopts advanced automatic feeding and discharging sealing system to improve the sealing performance of the furnace. So the waste pyrolysis is carried out under anaerobic condition, thus preventing the generation of dioxin. This can ensure the safe production of the pyrolysis furnace and prevent or reduce environmental pollution.

Low production cost

This furnace is equipped with highly efficient recovery system of combustible gas, so that the noncondensable gas can be used efficiently. This can greatly reduce energy consumption as well as emission of harmful gas.

Links:https://www.globefindpro.com/products/51621.html

-

BL-933 Double Bowl Stainless Steel Kitchen Sink

BL-933 Double Bowl Stainless Steel Kitchen Sink

-

BL-619 Single Bowl Stainless Steel Kitchen Sink

BL-619 Single Bowl Stainless Steel Kitchen Sink

-

BL-833 Rectangular Stainless Steel Kitchen Sink

BL-833 Rectangular Stainless Steel Kitchen Sink

-

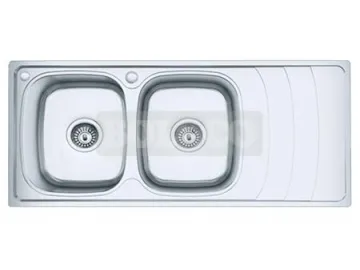

BL-938 Stainless Steel Double Bowl Kitchen Sink with Drainboard

BL-938 Stainless Steel Double Bowl Kitchen Sink with Drainboard

-

BL-610 Satin Finish Single Bowl Stainless Steel Kitchen Sink

BL-610 Satin Finish Single Bowl Stainless Steel Kitchen Sink

-

BL-936 Double Bowl Stainless Steel Kitchen Sink

BL-936 Double Bowl Stainless Steel Kitchen Sink

-

BL-601 Single Bowl Stainless Steel Kitchen Sink

BL-601 Single Bowl Stainless Steel Kitchen Sink

-

BL-934 Double Bowl Satin Finish Stainless Steel Kitchen Sink

BL-934 Double Bowl Satin Finish Stainless Steel Kitchen Sink

-

BL-603 Stainless Steel Single Bowl Kitchen Sink

BL-603 Stainless Steel Single Bowl Kitchen Sink

-

BL-999 Double Bowl Stainless Steel Drainboard Corner Kitchen Sink

BL-999 Double Bowl Stainless Steel Drainboard Corner Kitchen Sink

-

SY80B8 Standy Power 81KW 6-Cylinder Diesel Engine

SY80B8 Standy Power 81KW 6-Cylinder Diesel Engine

-

Waste Screw Conveyor Equipment

Waste Screw Conveyor Equipment