2000B 6-7 Inches Aluminium Extrusion Process

(6''-7'') 2000B :This quenching system is special designed for the billet range of 6-7 inches and corresponding extruder tonnage. As a standard model, it is among one of our best selling products. It is suitable for all types of alloy quenching treatment, comprised of water cooling, mist cooling and air cooling, and can be managed freely as per requirements.

Applicable types and materials

| ■ Tube, bar |

| ■ Irregular shape materials |

| ■ Aluminum or aluminum alloy 1000 series, 2000 series, 3000 series, 4000 series, 5000 series, 6000 series. |

Technical parameters

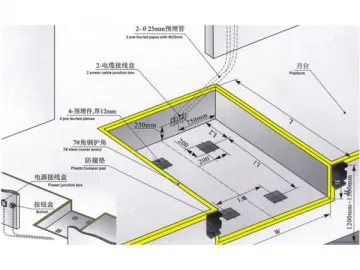

| 1 | Extruding billet spec.: diameter φ 152mm---178mm | 6 "---7" |

| 2 | Profile envelope : width is 250mm, height 200mm | 250mm, 200mm |

| 3 | Required space for the production line | 5600mm |

| 4 | Min. Space from the center line of press to workshop wall | 2800mm |

| 5 | Max. working power | 65kw |

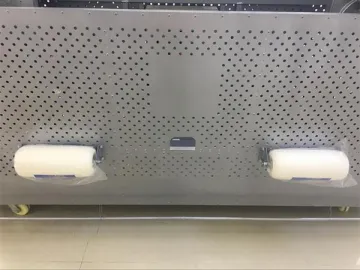

| 6 | Air cooling nozzles | 4 columns |

| 7 | Water cooling nozzles | 4 columns |

| 8 | Mist cooling nozzles | 4 columns |

| 9 | Min. flow of industrial softened water per quenching system | 80M³ |

| 10 | Water hardness | 3 ~ 5 ° F |

| 11 | Inlet water temp. at quenching system | < 35 ° C |

| 12 | Compressed air pressure at top | 6 Bar |

| 13 | Max. flow rate | 3 m3/min |

Scan QR to Read

Links:https://www.globefindpro.com/products/52176.html

Links:https://www.globefindpro.com/products/52176.html

Recommended Products

-

MH75/100/150 Material Hoist

MH75/100/150 Material Hoist

-

3000B 8-10 Inches Aluminium Extrusion Process

3000B 8-10 Inches Aluminium Extrusion Process

-

Steel Wire Rope

Steel Wire Rope

-

Aluminum Billet Heat Treat Furnace

Aluminum Billet Heat Treat Furnace

-

6000A 14-16 Inches Aluminum Extrusion Process

6000A 14-16 Inches Aluminum Extrusion Process

-

Safety Rope

Safety Rope

-

Fixed Hydraulic Dock Leveler

Fixed Hydraulic Dock Leveler

-

Building Maintenance Unit

Building Maintenance Unit

-

ZLP150 Suspended Chair

ZLP150 Suspended Chair

-

3000C 8-10 Inches Aluminum Extrusion Process

3000C 8-10 Inches Aluminum Extrusion Process

-

1000C 3-5 Inches Aluminium Extrusion Process

1000C 3-5 Inches Aluminium Extrusion Process

-

Construction Accessories

Construction Accessories

Hot Products