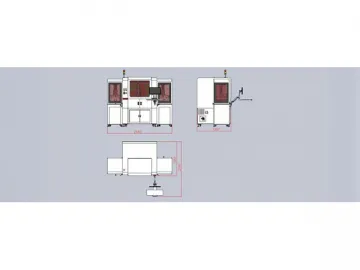

4000A 11-13 Inches Aluminum Extrusion Process

(9''-13'') 4000A: This quenching system is special designed for billet diameter range of 8-10 inches and corresponding extruder tonnage, which is used with profiles with large wall thickness. Based on B model, this design increases the lengths of air cooling at the backside, to ensure optimal cooling effect and minimize deformation under high speed extrusion. It is widely working with large extruder.

Main Tech. Data

| 1 | Billet spec.: diameter φ228mm---φ330mm | 9 "---13" |

| 2 | Profile envelope : width is 480mm, height 350mm | 480mm,350mm |

| 3 | Required space for the production line | 13500m |

| 4 | Min. space from the center line of press to workshop wall | 2800mm |

| 5 | Max. working power | 195kw |

| 6 | Front air cooling nozzles | 6 columns |

| 7 | Rear air cooling nozzles | 2 columns |

| 8 | Water cooling nozzles | 6 columns |

| 9 | Mist cooling nozzles | 6 columns |

| 10 | Min. flow of industrial softened water per quenching system | 180m³ |

| 11 | Water hardness | 3 ~ 5 °F |

| 12 | Inlet water temp. at quenching system | < 35 °C |

| 13 | Compressed air pressure at top | 6 Bar |

| 14 | Max. flow rate | 3m3/min |

Scan QR to Read

Links:https://www.globefindpro.com/products/52192.html

Links:https://www.globefindpro.com/products/52192.html

Recommended Products

-

Touch Screen Edge Bonding Machine

Touch Screen Edge Bonding Machine

-

Charge Coupled Device Inspection Machine

Charge Coupled Device Inspection Machine

-

FPC Laminating Machine

FPC Laminating Machine

-

500-3000kg Hydraulic Cargo Lift

500-3000kg Hydraulic Cargo Lift

-

ZLP630 Steel Suspended Work Platform

ZLP630 Steel Suspended Work Platform

-

Optically Clear Adhesive Rotary Die Cutting Machine

Optically Clear Adhesive Rotary Die Cutting Machine

-

Fixed Loading Dock Lift Table

Fixed Loading Dock Lift Table

-

Safety Lock

Safety Lock

-

Counterweight

Counterweight

-

Telescopic High Rise Aerial Lift Platform

Telescopic High Rise Aerial Lift Platform

-

2000C 6-7 Inches Aluminium Extrusion Process

2000C 6-7 Inches Aluminium Extrusion Process

-

Hoist

Hoist