Roller Hearth Furnace

Roller hearth furnace is a highly-efficient sintering equipment of large production capacity and small energy consumption. In early time, people applied it to produce ceramic tile, bathroom accessories, and other ceramic products. The development of silicon carbide roll, which allows the furnace temperature to be 1250℃, makes this thermal treating machinery a popular in processing lithium battery, magnetic material, metal powder, and ceramic products. Roller hearth furnace is also widely used for manufacturing lithium cobalt oxide, lithium manganese oxide, lithium material, cobalt oxide, pearl powder, and petroleum catalyst, with the furnace temperature lower than 1300℃.

Roller hearth furnace is a continuous tunnel furnace using roller to carry the raw materials. The products to be processed are placed on horizontal refractory rollers and pass through the furnace driven by the rollers. Roller hearth furnace is developed from traditional air sintering furnace, with an additional function of product sealing. Users can supply different gas into the furnace according to different product requirements.

Changyuan roller hearth furnace is consisted of 4 parts: the sintering part, the atmosphere adjustment system, the driving system, and the control system for temperature and material feeding. The atmosphere adjustment system incorporates the gas pipeline and the waste gas incineration system; and the driving system is comprised of inlet sealed cabin, outlet sealed cabin, and transmission device.

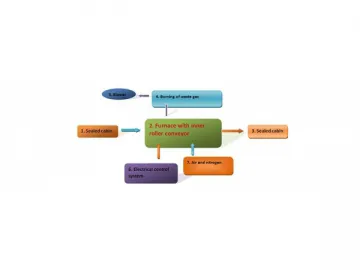

Working Process of Roller Hearth Furnace

a. The products are put in special container and sent into the furnace (2) through a sealed cabin (1) at the inlet by a transmission device

b. After heating stage, constant temperature stage, cooling part, and water cooling stage, the products enter a sealed cabin (3) at the outlet are finally taken out of the furnace

c. In the sintering process, the electrical control system (6) works continuously to heat the furnace, and air and nitrogen enters the furnace. Waste gases are burnt (4) and exhausted out of the furnace by the blower (5)

Technical Parameters

| Item | Roller hearth furnace | |||

| GD-80-11 | GD-180-11 | GD-300-12 | GD-800-11 | |

| Rated heating power (kw) | 80 | 180 | 300 | 800 |

| Voltage/phase (V/P) | 380/3 | |||

| Furnace dimension (L*W*H) (mm) | 41000*780*200 | 15000*1100*100 | 30000*800*200 | 80000*800*240 |

| Roller space (mm) | ∅42 | ∅42 | ∅55 | ∅60 |

| Max temperature (℃) | 1200 | |||

| Working temperature (℃) | no more than 1050℃ | |||

| Heating device | high temperature resistance wire (silicon carbide rod) | |||

| Regional division | 9 | 7 | 18 | 38 |

| Temperature control point | 13 | 7 | 36 | 38 |

| Temperature volatility (℃) | ≤±1 | |||

| Furnace section temperature (℃) | ≤±5 | |||

| Thermocouple | K | |||

| Temperature control | imported intelligent instrument; PID and SCR control | |||

| Speed (mm/h) | 150-1000 | 400-1500 | 400-2000 | 1000-4000 |

Remark: our sintering furnace can be designed according to clients’ requirements. For more specifications and details please contact us.

Links:https://www.globefindpro.com/products/52320.html

-

Copper Wire Cloth

Copper Wire Cloth

-

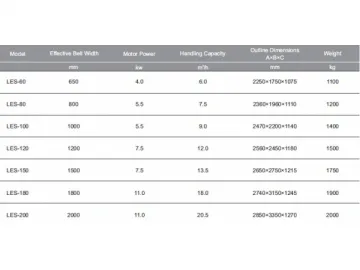

LES Eddy Current Separator

LES Eddy Current Separator

-

Safflower seed oil

Safflower seed oil

-

Pumpkin seed protein powder

Pumpkin seed protein powder

-

Carbon Steel Woven Wire Cloth

Carbon Steel Woven Wire Cloth

-

50AH-300AH VRLA Battery

50AH-300AH VRLA Battery

-

DD6851EV4 Public Electric Bus

DD6851EV4 Public Electric Bus

-

DD6119C31N Tourist Coach Bus

DD6119C31N Tourist Coach Bus

-

DD6120CHEV1N Hybrid City Bus

DD6120CHEV1N Hybrid City Bus

-

DD6100EV1 Electric City Bus

DD6100EV1 Electric City Bus

-

Air Atmosphere Sintering Furnace (Double Pusher Plate)

Air Atmosphere Sintering Furnace (Double Pusher Plate)

-

DD6535AML Minibus

DD6535AML Minibus