Large Format Laser Cutting and Engraving System

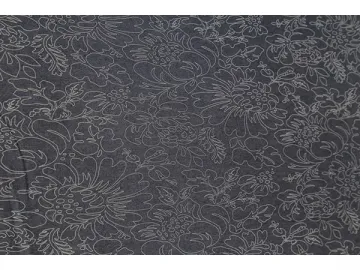

The large format laser cutting and engraving system is most often used to engrave, cut and drill materials like fabrics, leather and textiles. Equipped with an intelligent engraving software, the large format industrial laser cutting and engraving machine is easy to operate and saves a lot of processing time, greatly improving the working efficiency. A wide application is found in garment, shoemaking and leather industries.

Features of Large Format Laser Cutting and Engraving System

1. The laser marking and engraving system is specially produced for continuously engraving on home textiles and has a 1,800mm wide worktable.

2. Outfitted with a state-of-the-art galvo scanner and adopting ultra-high speed engraving technology, the large format laser machine offers fast speed, excellent engraving effect and smooth and neat joint. It’s ideally suitable for large format materials, with an incredible final quality.

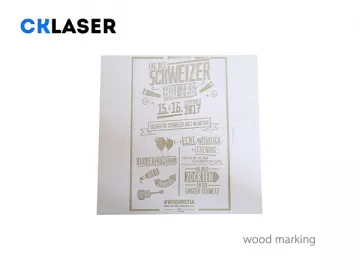

3. Instead of traditional printing and dyeing method, the laser cutting and engraving machine implements laser thermal processing method, which is noted for zero pollution, excellent color fastness, short process-cycle, easy and convenient image design, clean pattern and 3D effect.

4. The 350W RF carbon dioxide laser contributes to fast processing speed and fine effect.

5. The laser engraving and cutting machine realizes on-line and off-line operation as well as supports multiple formats of files, including PLT, DXF, DWG, BMP, JPG and so forth.

Specifications of Large Format Laser Cutting and Engraving System

| Model | CK-AF-1600 | |||

| Wavelength | 10640nm | |||

| Average Power | 350W | 400W | 600W | 1500 |

| Pulse Repetition Frequency | 2-100KHz | |||

| Beam Quality M2 | 0.8<M2<1.2 | |||

| Marking Range | Length:No limitation ,width:1600mm or 1800mm | |||

| Marking Speed | ≤10000mm/s | |||

| Mini line Width | 1mm,depending on the material | |||

| Repeat accuracy | 0.01m | |||

| Cooling sysytem | Water cooling | |||

| Voltage | 200VAV/10A/50-60HZ | |||

| Power Consumption | 8000W | 14000W | 17000W | 29000W |

| Environment | Temperature 15-35℃/Humidity30-80% | |||

| Size of machine | 3300mm×2656mm×2384mm | |||

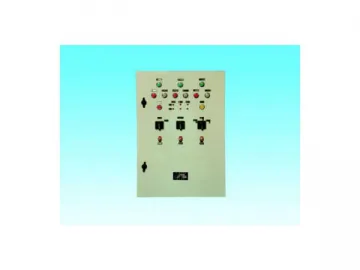

| Size of Control cabinet | 650mm×650mm×880.5mm | |||

| Size of Control chiller | 400mm×500mm×950mm | |||

Samples

Links:https://www.globefindpro.com/products/52420.html

-

JSR1 Series

JSR1 Series

-

Mini Type Desktop Laser Marker

Mini Type Desktop Laser Marker

-

3D CO2 Laser Marker

3D CO2 Laser Marker

-

Multi-material Injection Molding Machine for Plastic and LSR

Multi-material Injection Molding Machine for Plastic and LSR

-

Liquid Silicone Rubber Dosing System

Liquid Silicone Rubber Dosing System

-

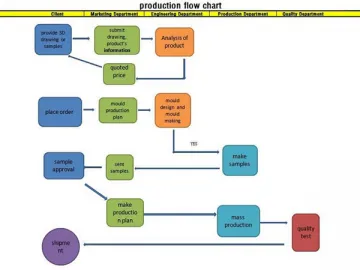

Production Flowchart

Production Flowchart

-

Silicone Baby Toothbrush

Silicone Baby Toothbrush

-

Circular Flap Valve

Circular Flap Valve

-

JSK-80 Series

JSK-80 Series

-

Double Door Flap Valve (left & right door)

Double Door Flap Valve (left & right door)

-

Elevator Buffer Springs

Elevator Buffer Springs

-

Hydraulic Flap Valve

Hydraulic Flap Valve