Polystyrene Foam (EPS) Sandwich Panel

EPS roofing panels (polyurethane sandwich roof panels) are composed of 2 layers of colored steel sheets with a polystyrene foam injected between the sheets to act as insulation material.

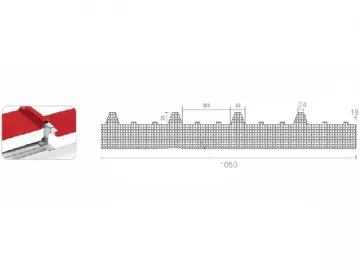

Both sides of the sandwich panel are made of galvanized stainless steel and aluminum steel sheets with an EPS foam core. (Please see the following picture). The steel is pressed using an automated continuous molding machines and binds together using polystyrene as a high strength adhesive bonding agent.

Applications

It is widely used in factory buildings, cleaning workshops, office buildings, clean rooms, room partitions, villas, stadiums and more.

| Item | Data |

| Effective Width of Wall Panels | 1150MM/950MM |

| Effective Width of Roof Panels | 1050MM/840MM |

| Length | Can be customized |

| Structure | Upper and lower layer: Color steel sheet Middle: EPS foam board |

| Density of EPS | 8-25KG/M3 |

| Thickness of steel sheet | 0.3-0.8MM |

| Thickness of EPS | 30 MM-250MM |

| Colors | Blue, white or according to your requirements |

Characteristics

1. Light weight

2. Good heat insulation

3. Low cost

4. Easy installation andremoval

Details

Dimension

Scan QR to Read

Links:https://www.globefindpro.com/products/52438.html

Links:https://www.globefindpro.com/products/52438.html

Recommended Products

-

TYM-W4545 Liquid Silicone Injection Molding Machine

TYM-W4545 Liquid Silicone Injection Molding Machine

-

TYM-4048-2 Liquid Silicone Injection Molding Machine

TYM-4048-2 Liquid Silicone Injection Molding Machine

-

TYM-6068-2 Liquid Silicone Injection Molding Machine

TYM-6068-2 Liquid Silicone Injection Molding Machine

-

3D UV Laser Marker

3D UV Laser Marker

-

Magnesium Oxide (MGO) Sandwich Panel

Magnesium Oxide (MGO) Sandwich Panel

-

Custom Silicone Parts

Custom Silicone Parts

-

Silicone O Ring

Silicone O Ring

-

TYM-5058-2 Liquid Silicone Injection Molding Machine

TYM-5058-2 Liquid Silicone Injection Molding Machine

-

Silicone Nipple Shield

Silicone Nipple Shield

-

Silicone Baby Teether

Silicone Baby Teether

-

TYM-W5050 Liquid Silicone Injection Molding Machine

TYM-W5050 Liquid Silicone Injection Molding Machine

-

TYM-4048 Liquid Silicone Injection Molding Machine

TYM-4048 Liquid Silicone Injection Molding Machine