Circular Bulk Bags

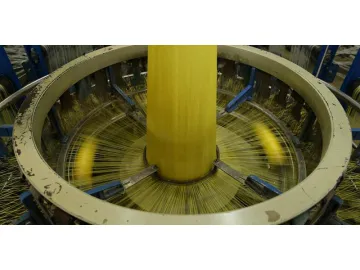

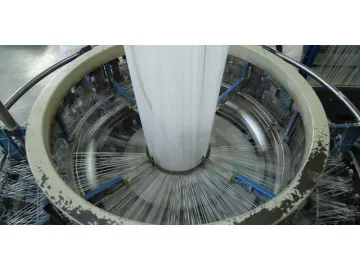

The circular bulk bags has no side sewing procedures, and only the top and bottom panels are hemmed. Circular bags are ideal packaging carriers for precise and hygroscopic materials, due to the improvement of the moisture resistant property. This design makes it suitable for hygroscopic and fine particles, and thus it is the preferred choice for finer chemicals packaging.

Customize your FIBCs, please click

Application

Chemical raw materials, chemical fertilizers, cements, sand, mineral powders, carbon black, food, flour, sugar, peanuts, seeds

Parameters

Safe Working Load 1250kg

Insurance coefficient 6: 1

Size 90x90x120cm

Fabric 185gsm, coated or uncoated with UV

Printing both sides can be printed, 4 colors at most

Color white, brown, yellow or customers assigned

Top filling spout, easy for bagging

Bottom cone bottom and full open

Loop construction stand open cross-corner lift loops

Features

Appearance: due to the elimination of the side seam, the bulk bags have a more attractive appearance. Function: the improvement of moisture resistant properties make it suitable for hygroscopic and finer particles. Manufacturing: only the top and bottom are sewn. Pattern: any pattern customers want can be printed and will not scratch or be rubbed off during packaging and transportation Lifting method: the baffled bulk bags have three types of lifting structures: top lifting type, side lifting type and bottom lifting type, and can be lifted by forklifts. Fabric is 100% recyclable

Processing advantages of Boda FIBCs

17 years of production experience The technicians can help design the packaging solutions you want. The FIBCs have passed FDA certification and UV certification. The factory is equipped with Austrian Starlinger winding lines. Monthly output of 1500 tons of FIBC bags. The inventory is controlled by a unified management procedure with orderly and fast supply.

Related

bulk bags, ton bag, big bag

Scan QR to Read

Links:https://www.globefindpro.com/products/52614.html

Links:https://www.globefindpro.com/products/52614.html

Recommended Products