Belt Cleaners / Scrapers

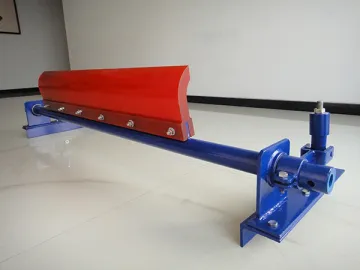

Polyurethane Belt Cleaner/Scraper

Polyurethane belt scraper is made through one-piece casting with polyurethane. One of its prominent features is excellent wear resistance because polyurethane elastomer used has extraordinary wear-ability. Being tested, wear-ability of polyurethane is normally ranging from 0.03 to 0.20 mm3/m, which is 3 to 5 times of that of natural rubber.

Wear-ability is closely related to material's tear strength and surface conditions. Polyurethane elastomer's tear strength is much higher than different kinds of rubber. However, its friction coefficient is not low and often exceeds 0.5. Hence, it is necessary to add proper amount of oil lubricants, molybdenum disulfide, graphite, silicone oil, or tetrafluoroethylene powder into polyurethane used to make the scraper to lower friction coefficient, thus reducing heat generation by friction. Furthermore, friction coefficient is also affected by factors such as material hardness and surface temperature. In all situations, friction coefficient improves as hardness decreases. It also rises with surface temperature increasing and reaches the maximum at 90℃.

The cleaner comes with a spring tension regulator, which enables the scraper to automatically follow up and make compensation when the scarper wears out or the belt jumps. In this way, the scraper will be always pressed against the belt, thus ensuring high removal efficiency.

Applicable Situations

1. Belt Width: B=500~2200mm

2. Belt Speed: ≤3.5(m/s)

3. Material Humidity: ≤15%

4. Working Temperature: -40℃~90℃.

Links:https://www.globefindpro.com/products/52895.html

-

High Pressure Centrifugal Fan

High Pressure Centrifugal Fan

-

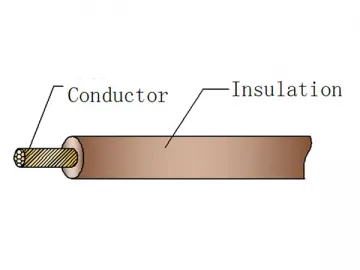

PVC Compounds for Wires and Cables

PVC Compounds for Wires and Cables

-

Dual Pressure Control

Dual Pressure Control

-

CCC Approved Power Cord

CCC Approved Power Cord

-

Hook-Up Wire, UL2725

Hook-Up Wire, UL2725

-

Stainless Steel Flow Switch

Stainless Steel Flow Switch

-

Hook-Up Wire, UL1095

Hook-Up Wire, UL1095

-

Hook-Up Wire, UL1007

Hook-Up Wire, UL1007

-

Hook-Up Wire, UL1019

Hook-Up Wire, UL1019

-

Centrifugal Fan, 4-72 Series

Centrifugal Fan, 4-72 Series

-

Japanese Standard Automotive Wire

Japanese Standard Automotive Wire

-

Hook-Up Wire, UL1569

Hook-Up Wire, UL1569