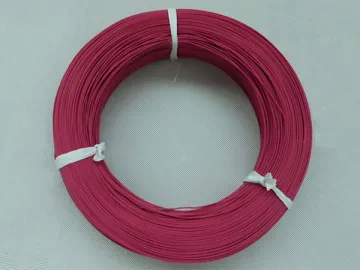

Hook-Up Wire, UL2725

About UL2725

Manufacture standard: UL758

Rated voltage: 30 Vac

Temperature range: -40 to 80℃

Conductor: Bare copper

Insulator: PVC

Flame retardant performance: Passing UL VW-1 and CSA FT1 vertical flame tests

Environmental protection: ROHS standard

Color: Black, brown, red, orange, yellow, green, blue, purple, gray and white.

Application: Internal wiring and electronic equipment

Technical Parameters of UL Hook up Wire

| Conductor | Core number | Insulator | Shielding material | Protective cover | Conductor resistance (Bare copper) | Standard length | |||||

| Wire gauge | Structure | Diameter | Nominal thickness | Nominal external diameter | Nominal thickness | Nominal external diameter | Max. value (20℃) | English unit | Metric unit | ||

| AWG | NO/Φmm | mm | NO. | mm | mm | mm | mm | Ω /km | FT | m | |

| 30 | 7/0.10 | 0.30 | 2 | 0.23 | 0.8±0.1 | AL-mylar | 0.4 | 2.6 | 354 | 2000 | 610 |

| 3 | 0.8±0.1 | AL-mylar | 0.4 | 2.8 | |||||||

| 4 | 0.8±0.1 | AL-mylar | 0.4 | 3.0 | |||||||

| 5 | 0.8±0.1 | AL-mylar | 0.45 | 3.2 | |||||||

| 6 | 0.8±0.1 | AL-mylar | 0.45 | 3.5 | |||||||

| 7 | 0.8±0.1 | AL-mylar | 0.45 | 3.5 | |||||||

| 28 | 7/0.127 | 0.38 | 2 | 0.23 | 0.9±0.1 | AL-mylar | 0.4 | 2.8 | 223 | 2000 | 610 |

| 3 | 0.9±0.1 | AL-mylar | 0.4 | 3.0 | |||||||

| 4 | 0.9±0.1 | AL-mylar | 0.4 | 3.2 | |||||||

| 5 | 0.9±0.1 | AL-mylar | 0.45 | 3.5 | |||||||

| 6 | 0.9±0.1 | AL-mylar | 0.45 | 3.8 | |||||||

| 7 | 0.9±0.1 | AL-mylar | 0.45 | 3.8 | |||||||

| 26 | 7/0.16 | 0.48 | 2 | 0.23 | 1.0±0.1 | AL-mylar | 0.43 | 3.0 | 140 | 2000 | 610 |

| 3 | 1.0±0.1 | AL-mylar | 0.43 | 3.2 | |||||||

| 4 | 1.0±0.1 | AL-mylar | 0.43 | 3.5 | |||||||

| 5 | 1.0±0.1 | AL-mylar | 0.45 | 3.8 | |||||||

| 6 | 1.0±0.1 | AL-mylar | 0.45 | 4.0 | |||||||

| 7 | 1.0±0.1 | AL-mylar | 0.45 | 4.0 | |||||||

| 24 | 11/0.16 | 0.61 | 2 | 0.26 | 1.2±0.1 | AL-mylar | 0.45 | 3.5 | 87.6 | 2000 | 610 |

| 3 | 1.2±0.1 | AL-mylar | 0.45 | 3.6 | |||||||

| 4 | 1.2±0.1 | AL-mylar | 0.45 | 4.0 | |||||||

| 5 | 1.2±0.1 | AL-mylar | 0.45 | 4.3 | 1000 | 305 | |||||

| 6 | 1.2±0.1 | AL-mylar | 0.45 | 4.6 | |||||||

| 7 | 1.2±0.1 | AL-mylar | 0.45 | 4.6 | |||||||

| 22 | 17/0.16 | 0.76 | 2 | 0.26 | 1.3±0.1 | AL-mylar | 0.45 | 3.6 | 55.4 | 1000 | 305 |

| 3 | 1.3±0.1 | AL-mylar | 0.45 | 3.8 | |||||||

| 4 | 1.3±0.1 | AL-mylar | 0.45 | 4.2 | |||||||

| 5 | 1.3±0.1 | AL-mylar | 0.45 | 4.6 | |||||||

| 6 | 1.3±0.1 | AL-mylar | 0.45 | 5.0 | |||||||

| 7 | 1.3±0.1 | AL-mylar | 0.45 | 5.0 | |||||||

| Notes: 1. We can manufacture the hook-up wire according to client's drawing or sample. 2. The structure of conductor is either solid or stranded. For example, "7/0.10" means the conductor is stranded by 7 wires and the wire has a diameter of 0.10 mm. | |||||||||||

Scan QR to Read

Links:https://www.globefindpro.com/products/52900.html

Links:https://www.globefindpro.com/products/52900.html

Recommended Products

-

Stainless Steel Flow Switch

Stainless Steel Flow Switch

-

Direct Acting Solenoid Valve

Direct Acting Solenoid Valve

-

Power Cable, Euro 2 Pin Plug

Power Cable, Euro 2 Pin Plug

-

Hook-Up Wire, UL1571

Hook-Up Wire, UL1571

-

Hook-Up Wire, UL1430

Hook-Up Wire, UL1430

-

Hook-Up Wire, UL1011

Hook-Up Wire, UL1011

-

CCC Approved Power Cord

CCC Approved Power Cord

-

Dual Pressure Control

Dual Pressure Control

-

PVC Compounds for Wires and Cables

PVC Compounds for Wires and Cables

-

High Pressure Centrifugal Fan

High Pressure Centrifugal Fan

-

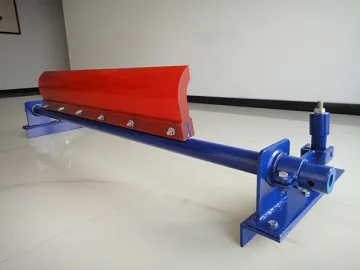

Belt Cleaners / Scrapers

Belt Cleaners / Scrapers

-

Hook-Up Wire, UL1095

Hook-Up Wire, UL1095