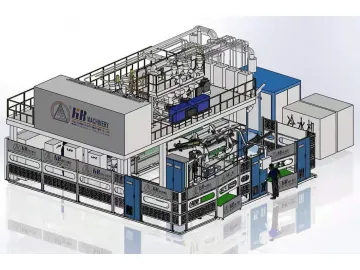

CPET/OPET Plastic Extrusion Cast Film Line

This film extrusion line is particularly designed to produce eco-friendly CPET and OPET films by extrusion using PET plastic (polyethylene terephthalate). The OPET film is produced through mono-orientation stretching process, which can be an ideal alternative to PVC film, BOPET film and BOPP film in packaging field, thus greatly reducing the costs of equipment investment and film production.

Features

Single-screw or twin-screw extruder, can produce single-layer, double-layer or three-layer co-extruded cast film;

Adapting to the properties of PET or modified PET materials, specially designed extrusion process is implemented along with various units including drying unit, automatic dosing unit, plasticizing extruder, T-die, chill roll unit, automatic thickness gauge, pre-heating & stretching unit, surface treatment unit, edge trims handling system and fully automatic winder to manufacture high quality functional plastic films;

A selection of specifications are available to meet your requirements;

Applications

Tinplate laminated film

Electronics packaging film

Medical packaging film

Chemical coated film

Heat shrinkable film

Base film for solar control window film

CPET film can also be used for low temperature radiant heating, motor and generator insulation, electrical insulation, etc.

Get in touch with us

Scan QR to Read

Links:https://www.globefindpro.com/products/5296.html

Links:https://www.globefindpro.com/products/5296.html

Recommended Products

-

Single Corrugated Slitting Cutting and Stacking Machine,NCM-15D

Single Corrugated Slitting Cutting and Stacking Machine,NCM-15D

-

5-Layer PE Cling Film Line (4 Winding Shafts)

5-Layer PE Cling Film Line (4 Winding Shafts)

-

Semi-automatic Stitching Machine, 600 Stitches/min, BDJ-B

Semi-automatic Stitching Machine, 600 Stitches/min, BDJ-B

-

5-Layer PE Cling Film Line (2 Winding Shafts)

5-Layer PE Cling Film Line (2 Winding Shafts)

-

Cast Film Lines for PEVA Embossed Laminating Film (Single and Multi-Layer)

Cast Film Lines for PEVA Embossed Laminating Film (Single and Multi-Layer)

-

Cast Film Lines

Cast Film Lines

-

Cast Film Lines for PEVA Embossed Film (Single and Multi-Layer)

Cast Film Lines for PEVA Embossed Film (Single and Multi-Layer)

-

Automatic Stretch Film Rewinder

Automatic Stretch Film Rewinder

-

PP/PE Mono Oriented Film Line

PP/PE Mono Oriented Film Line

-

Down Stacker, HM-25A

Down Stacker, HM-25A

-

Slitting Cutting and Stacking System for Single Face Corrugated Board, NCM-15B

Slitting Cutting and Stacking System for Single Face Corrugated Board, NCM-15B

-

Clamshell Die Cutter

Clamshell Die Cutter

Hot Products