PVC-based WPC Wall Panel Extrusion Line

Production Line for Wall Panel, WPC Ceiling Extrusion Line, Extrusion Line for WPC Panel

PVC/based WPC wall panel extrusion line is characterized by automatic control, stable performance, easy operation, and high efficiency, By employing mods with different specifications, we can use this line to produce diversified specifications, sizes, shapes and thickness of WPC decorative wall panels, WPC wall panels, ecological wall panels, etc.

This wall panel extrusion line incorporates , molds, vacuum sizing machine, tractor, horizontal cutting machine, and stacker.

Applications: WPC door panels, WPC wall panels, PVC heat insulation hollow tiles, etc.

Advantages of WPC Wall Panel

As a kind of light composite material, WPC panel shows excellent performance in strength, impact resistance, heat and noise insulation, and resistance to fire, water, and shock. WPC wall panel can be slotted in any styles. It is also environmentally friendly and energy saving.

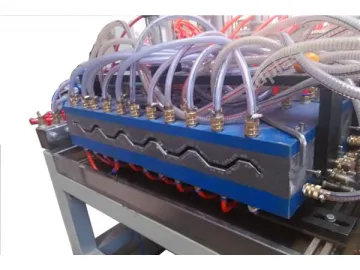

Shown are the molds for extruding WPC wall panels. Concentrated air cooling system is set for the convenience of operation and cooling the extrudered panels

Double Track Haul-Off Unit

Transverse Chip-Free Cutting Machine with certain cutting length

The cutting machine is equipped with a dust collection device to ensure the equipment and air is protected from dust pollution.

Transfer printing treatment for the wall panels

PVC-based WPC wall panels

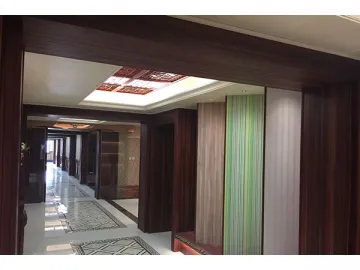

Indoor applications of WPC wall panels

WPC wall panels

Technical Parameters

| Model | Screw diameter | Power of main moor | Max panel width | Extrusion capacity |

| MSSZ65/132 | 65mm/132mm | 37 | 600mm | 50-250kgs/hr |

| MSSZ80/156 | 80mm/156mm | 55 | 820mm | 180-360kgs/hr |

Links:https://www.globefindpro.com/products/52968.html

-

PVC Corner Bead Extrusion Line

PVC Corner Bead Extrusion Line

-

Co-Rotating Twin Screw Pelletizing Line

Co-Rotating Twin Screw Pelletizing Line

-

WPC Extrusion Dies

WPC Extrusion Dies

-

Multi-Layer Sheet Co-Extrusion Line

Multi-Layer Sheet Co-Extrusion Line

-

PVC Door/Window Profile / Porous Threading Pipe Extrusion Line

PVC Door/Window Profile / Porous Threading Pipe Extrusion Line

-

Double Shaft Mixer

Double Shaft Mixer

-

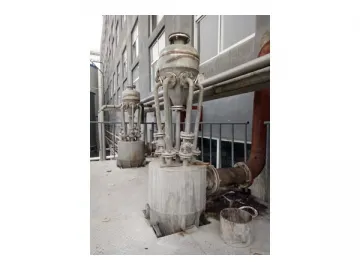

Falling Film Evaporator

Falling Film Evaporator

-

HDPE Conduit Extrusion Line

HDPE Conduit Extrusion Line

-

Jet Sulfur Dioxide Scrubber

Jet Sulfur Dioxide Scrubber

-

Corrugated Roofing Sheet Extrusion Line

Corrugated Roofing Sheet Extrusion Line

-

High Speed Cold/Hot Mixer

High Speed Cold/Hot Mixer

-

PVC/WPC Pelletizing Line

PVC/WPC Pelletizing Line