Double Shaft Mixer

Working Principle

In a double shaft mixer, the materials conduct compound motion under the action of 2 rotors moving at opposite directions. The blades drive the materials to perform anticlockwise rotation along the inner wall of the mixer. This movement has led to an area of weightlessness at the overlapping region of the 2 rotors. In this area, whatever is the materials’ shape or how much are their sizes or density, the materials will float in the air and comes into a weightless state immediately, and move in the mixer continuously and cyclically. In this way, the materials will be mixed gently, uniformly, and quickly.

Features & Applications

Double shaft mixer is mainly used for mixing thick slurry in starch, alcohol, and feed industries to ensure that in the material drying process, the wet materials won’t stick to the chamber of dryer.

This mixer features compact structure, uniform mixing effect, and no dirt. The production capacity is 5-100 t/h. The materials enter the chamber with a feeding machine. With the shafts distributed spirally on two sides of the blades rotating simultaneously, the wet materials will be discharged continuously through the outlet.

Our twin shaft mixer employs gland packaging and labyrinth seal methods for reliable sealing. The shaft is worn slightly. This mixer works reliably and is easy to be maintained.

Technical Parameters

| Model | HL2600 | HL3200 | Sj4500 | HL6000 | |

| Max transmission distance (mm) | 2600 | 3200 | 4500 | 6000 | |

| Production capacity (T) | 1-10 | 5-15 | 10-20 | 15-25 | |

| Speed of main shaft | 49 | 49 | 46 | 49 | |

| Reducer model | Jzq200 | Jzq200 | Jzq350 | Jzq400 | |

| Motor | model | Y112M | Y132S | Y132M | Y160M |

| power | 4 | 5.5 | 7.5 | 11 | |

Links:https://www.globefindpro.com/products/52974.html

-

Plastic/Rubber Crusher

Plastic/Rubber Crusher

-

Pneumatic Dryer

Pneumatic Dryer

-

PP Foam Sheet Extrusion Line

PP Foam Sheet Extrusion Line

-

Corrugated Pipe Extrusion Line

Corrugated Pipe Extrusion Line

-

Single Screw Extruder

Single Screw Extruder

-

PS Foam Profile Extrusion Line

PS Foam Profile Extrusion Line

-

PVC Door/Window Profile / Porous Threading Pipe Extrusion Line

PVC Door/Window Profile / Porous Threading Pipe Extrusion Line

-

Multi-Layer Sheet Co-Extrusion Line

Multi-Layer Sheet Co-Extrusion Line

-

WPC Extrusion Dies

WPC Extrusion Dies

-

Co-Rotating Twin Screw Pelletizing Line

Co-Rotating Twin Screw Pelletizing Line

-

PVC Corner Bead Extrusion Line

PVC Corner Bead Extrusion Line

-

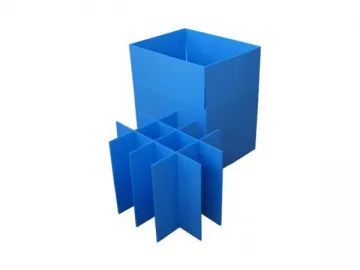

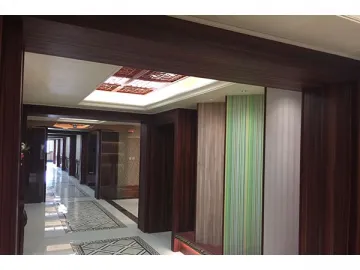

PVC-based WPC Wall Panel Extrusion Line

PVC-based WPC Wall Panel Extrusion Line