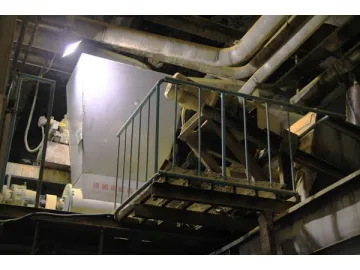

Tube Bundle Dryer

GZG series tube bundle dryer is an indirect heating type dryer, widely applied in drying loose materials without too much viscosity like powder, particulate, and bulk solids in chemical, light industry, food, and beverages industries. It is especially an ideal for drying corn germ, corn fiber (corn residue), and protein powder. This kind of tube dryer operates with little energy consumption, obvious drying effect, and high production efficiency. Both continuous and intermittent working modes are available for option. Users can apply it in drying materials with high water content. The successful development of GZG series tube bundle dryer is an innovation in Chinese drying industry.

Weitai provides more than 20 types of tube bundle dryers, which are diversified in specification from 40㎡ to 1500㎡. Clients are welcome to choose the required one according to their scale of production.

Technical Parameters

| Model | Dimension (mm) | Specification | |||||

| L×W×H | rotating speed m2 | heat exchange area (r.p.m) | water outlet | suction port | gas inlet | power (kw) | |

| GZG300 | 9910 ×2472×3250 | 5-8 | 300 | ZG3" | φ450 | ZG3" | 22 |

| GZG400 | 9700×2982×3963 | 5-8 | 400 | ZG3" | φ500 | ZG4" | 37 |

| GZG500 | 10200×2980×3963 | 5-8 | 500 | ZG3" | φ500 | ZG4" | 45 |

| GZG600 | 10960×3180×4260 | 5-8 | 600 | ZG4" | φ500 | ZG5" | 55 |

| GZG700 | 10685×3382×4480 | 5-8 | 700 | ZG4" | φ500 | ZG5" | 55 |

| GZG800 | 10685×3782×4980 | 5-8 | 800 | ZG5" | φ600 | ZG6" | 75 |

| GZG900 | 11680×3600×4470 | 5-8 | 900 | ZG5" | φ600 | ZG6" | 90 |

| GZG1000 | 12450×3600×4470 | 5-8 | 1000 | ZG6" | φ750 | ZG7" | 90 |

| GZG1100 | 13220×3600×4470 | 5-8 | 1100 | ZG6" | φ750 | ZG7" | 110 |

| GZG1200 | 14310×3500×4206 | 5-8 | 1200 | ZG6" | φ750 | ZG7" | 132 |

| GZG1300 | 15480×3746×4900 | 5-8 | 1300 | ZG6" | φ800 | ZG7" | 132 |

| GZG1400 | 14315×3948×5790 | 5-8 | 1400 | ZG7" | φ800 | ZG7" | 132 |

| GZG1500 | 14550×4160×6027 | 5-8 | 1500 | ZG7" | φ850 | ZG7" | 132 |

Applicable Materials and Parameters

| Common materials (light industry) | Water content (before) | Water content (after | Drying strength (evaporated water kg/m2) | Energy consumption (consumed energy/evaporated water) |

| Germ | 55% | 3-5% | 2.5-3 | 3500-3800 KJ/kg 840-910Kcal/kg (equivalent to 1.45-1.5kg standard saturated steam) |

| Corn fiber | 60% | 10-12% | 4.8 | |

| Bacterial protein powder | 65% | 10% | 3-4.7 | |

| Cassava fiber | 65% | 10-12% | 3.5-4.8 | |

| Distillers' grains | 65% | 10-12% | 3.5-4.9 | |

| Feed carrier | 18% | 6-8% | 2 | |

| Rapeseed | 16% | 11% | 3 | |

| Baking powder for pig blood | 35% | 10% | 2.5 | |

| Bone meal | 40% | 10% | 2.5 | |

| Fermented feed | 40% | 10% | 3 | |

| Corn residue, rice residue (citric acid, MSG residue) | 65% | 10-12% | 3.5 |

Links:https://www.globefindpro.com/products/52986.html

-

WPC Brushing Machine

WPC Brushing Machine

-

Wet Protein Crusher

Wet Protein Crusher

-

WPC Door Panel / PVC Hollow Thermal Tiles Extrusion Line

WPC Door Panel / PVC Hollow Thermal Tiles Extrusion Line

-

Embossing Machine

Embossing Machine

-

Hammer Mill

Hammer Mill

-

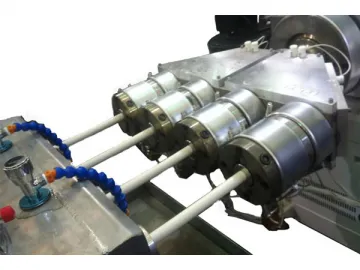

Pipe Extrusion Dies

Pipe Extrusion Dies

-

Laboratory Extruder

Laboratory Extruder

-

PVC Conduit Pipe Extrusion Line

PVC Conduit Pipe Extrusion Line

-

Germ Separation System / Germ Cyclone

Germ Separation System / Germ Cyclone

-

Multi Co-Extrusion Profile Extrusion Line

Multi Co-Extrusion Profile Extrusion Line

-

PVC Profiles Extrusion Dies

PVC Profiles Extrusion Dies

-

PS Foam Profile Extrusion Line

PS Foam Profile Extrusion Line