Solid Carbide Rod

Tungsten Carbide Round Rod, Solid Carbide Rod for Lathe Tool, Cemented Carbide Rod, Metal Working Tool

Solid carbide rod is one of the ultrafine grain products developed by CY CARBIDE after we have introduced the techniques from Japan, with all of the manufacturing processes accomplished in an independent ultrafine grain system. It is made from tungsten carbide powders with extra-fine grain size (0.6~0.7μm). The stable quality and performance has won it large popularity among European and other international markets.

CY CARBIDE has developed series of sub-micro grades with HIP treatment for the different applications of solid tungsten rods. Sintered blanks and H6 precision grinding are both available.

Application

Solid carbide round rod is a high-hardness high-strength alloy mainly composed of WC. It can be used as drills, milling cutters, and gun drills for processing steel, cast iron, stainless steel and Titanium alloy, etc.

Physical Properties

| Grade | Density g/cm3 | Hardness | T.R.S | Wear resistance | Impact strength | ||

| HRA | HV30 | N/mm2 | PSI | ||||

| MH6 | 14.95 | 94.0 | 2000 | 3200 | 464 000 | Very high | Medium |

| MH10 | 14.45 | 92.1 | 1620 | 3800 | 551 000 | Medium | High |

| MH12 | 14.30 | 92.5 | 1700 | 4000 | 580 000 | High | Very high |

| MH6 | MDF, HDF and other hard woods, PCB drills. |

| MH10, MH12 | Steel, cast iron, stainless steel and other alloys. |

Solid Rods (Metric) 330-Long

Metric

| Unground | h6 | L | TOL. | |

| D | Tol. | |||

| φ2.2 | 0.3/ 0 | 2.00 | 330 | 5/ 0 |

| φ3.2 | 3.00 | 330 | ||

| φ4.2 | 4.00 | 330 | ||

| φ5.2 | 5.00 | 330 | ||

| φ6.2 | 6.00 | 330 | ||

| φ7.2 | 7.00 | 330 | ||

| φ8.2 | 8.00 | 330 | ||

| φ9.2 | 9.00 | 330 | ||

| φ10.2 | 10.0 | 330 | ||

| φ11.2 | 0.4/ 0 | 11.0 | 330 | |

| φ12.2 | 12.0 | 330 | ||

| φ13.2 | 13.0 | 330 | ||

| φ14.2 | 14.0 | 330 | ||

| φ15.2 | 15.0 | 330 | ||

| φ16.2 | 16.0 | 330 | ||

| φ17.2 | 17.0 | 330 | ||

| φ18.2 | 18.0 | 330 | ||

| φ19.2 | 19.0 | 330 | ||

| φ20.2 | 0.5/ 0 | 20.0 | 330 | |

| φ21.2 | 21.0 | 330 | ||

| φ22.2 | 22.0 | 330 | ||

| φ23.2 | 23.0 | 330 | ||

| φ24.2 | 0.6/ 0 | 24.0 | 330 | |

| φ25.2 | 25.0 | 330 | ||

| φ26.2 | 26.0 | 330 | ||

| φ27.2 | 27.0 | 330 | ||

| φ28.2 | 28.0 | 330 | ||

| φ29.2 | 29.0 | 330 | ||

| φ30.2 | 30.0 | 330 | ||

Unground

| D | Tol. | L | Tol. | CX45° Tol. ±0.1 | D | Tol. | L | Tol. | CX45° Tol. ±0.1 |

| 3.0 | h6 / h5 | 39 | 0 / 1% of length, minimum 0.5 mm | 0.3 | 12.0 | h6 / h5 | 74 | 0 / 1% of length, minimum 0.5 mm | 0.8 |

| 3.0 | 52 | 0.3 | 12.0 | 84 | 0.8 | ||||

| 4.0 | 51 | 0.3 | 12.0 | 101 | 0.8 | ||||

| 4.0 | 55 | 0.3 | 14.0 | 76 | 0.8 | ||||

| 5.0 | 51 | 0.3 | 14.0 | 84 | 0.8 | ||||

| 5.0 | 55 | 0.3 | 14.0 | 89 | 0.8 | ||||

| 6.0 | 51 | 0.4 | 16.0 | 83 | 0.8 | ||||

| 6.0 | 55 | 0.4 | 16.0 | 93 | 0.8 | ||||

| 6.0 | 58 | 0.4 | 16.0 | 108 | 0.8 | ||||

| 6.0 | 66 | 0.4 | 16.0 | 125 | 0.8 | ||||

| 8.0 | 59 | 0.6 | 18.0 | 85 | 1.0 | ||||

| 8.0 | 64 | 0.6 | 18.0 | 93 | 1.0 | ||||

| 8.0 | 80 | 0.6 | 20.0 | 93 | 1.0 | ||||

| 10.0 | 67 | 0.6 | 20.0 | 105 | 1.0 | ||||

| 10.0 | 73 | 0.6 | 25.0 | 103 | 2.0 | ||||

| 10.0 | 89 | 0.6 | 25.0 | 151 | 2.0 |

| D | Tol. | L | Tol. | CX45° Tol.±0.004 | |||||||

| 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 13 | ||||

| 1/8 | h6/h5 | ● | ● | ● | ● | ● | 0/ 1% of length,minimum 0.02" | 0.012 | |||

| 3/16 | h6/h5 | ● | ● | ● | ● | ● | ● | ● | 0.016 | ||

| 1/4 | h6/h5 | ● | ● | ● | ● | ● | ● | ● | 0.024 | ||

| 5/16 | h6/h5 | ● | ● | ● | ● | ● | ● | 0.024 | |||

| 3/8 | h6/h5 | ● | ● | ● | ● | ● | ● | ● | 0.024 | ||

| 7/16 | h6/h5 | ● | ● | ● | ● | ● | ● | 0.031 | |||

| 1/2 | h6/h5 | ● | ● | ● | ● | ● | ● | 0.031 | |||

| 9/16 | h6/h5 | ● | ● | 0.031 | |||||||

| 5/8 | h6/h5 | ● | ● | ● | ● | ● | 0.031 | ||||

| 3/4 | h6/h5 | ● | ● | ● | ● | ● | ● | 0.039 | |||

| 7/8 | h6/h5 | ● | ● | ● | ● | 0.039 | |||||

| 1 | h6/h5 | ● | ● | ● | ● | ● | ● | 0.039 | |||

| 1 1/4 | h6/h5 | ● | ● | ● | ● | 0.059 | |||||

| 1 1/2 | h6/h5 | ● | ● | 0.069 | |||||||

Links:https://www.globefindpro.com/products/53086.html

-

Steel Sheet

Steel Sheet

-

Galvalume Steel Coil

Galvalume Steel Coil

-

ADSS Optical Fiber Cable

ADSS Optical Fiber Cable

-

Aluminum Conductor Steel Reinforced (ACSR)

Aluminum Conductor Steel Reinforced (ACSR)

-

0.6/1KV Waterproofed XLPE Insulated Power Cable

0.6/1KV Waterproofed XLPE Insulated Power Cable

-

Solar PV Cable

Solar PV Cable

-

Carbide Insert for Round Shank Picks

Carbide Insert for Round Shank Picks

-

Ready to Press Grade Powder (RTP)

Ready to Press Grade Powder (RTP)

-

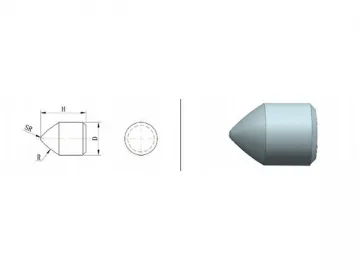

Carbide Insert for Tunnel Boring

Carbide Insert for Tunnel Boring

-

Carbide Blank for Circular Blades / Knives

Carbide Blank for Circular Blades / Knives

-

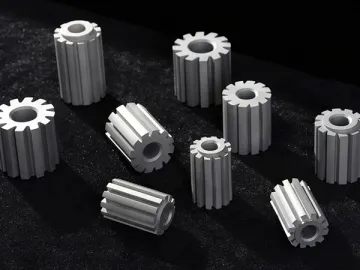

Gear Hob Blanks

Gear Hob Blanks

-

Carbide Button Insert

Carbide Button Insert