Crude Oil Refining Plant

Working Principle  Pyrolysis furnace Oil storage tank Heat exchanger Water sealing tube Final diesel

Pyrolysis furnace Oil storage tank Heat exchanger Water sealing tube Final diesel

Technical Parameters

Thecrude oil refining plant puts the oil to be deeply processed into the pyrolysis furnace with an oil pump. Under atmospheric pressure, the oil is heated and condensed into petrol and diesel through a distillation tower. The non-condensable gas will be sent to the furnace as fuel by water sealing device and flame arrester. In this way, the thermal energy is utilized effectively. The residues are discharged regularly.

Technical Parameters

| Model | YTNY-JL50 | YTNY-JL100 | YTNY-JL300 |

| Raw material | crude oil | ||

| Daily processing capacity | 50t | 100t | 300t |

| Working style | continuous (the whole process consuming 7-8 hours can be finished with 1 furnace uninterruptedly) | ||

| Oil yield (at least) | 85%-95% | ||

| Pressure | atmospheric pressure | ||

| Power | 80kw | 100kw | 140kw |

| Noise dB (A) | ≤85 | ||

| Cooling method | water cooling | ||

| Fuel | coal, natural gas, fuel oil, wood | ||

| Installation | under our instruction | ||

| Acreage | 45*140m | 45*145m | 55*165m |

| Final product | non-standard diesel | ||

Scan QR to Read

Links:https://www.globefindpro.com/products/53163.html

Links:https://www.globefindpro.com/products/53163.html

Recommended Products

-

Window Screen

Window Screen

-

Tower Crane

Tower Crane

-

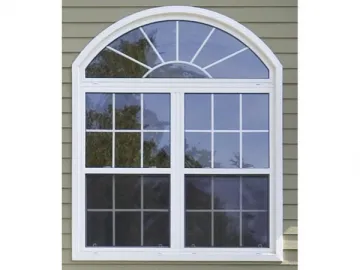

Casement Windows & Doors

Casement Windows & Doors

-

Sliding Windows & Doors

Sliding Windows & Doors

-

Biodiesel Fuel

Biodiesel Fuel

-

Batch Type Waste Pyrolysis Plant

Batch Type Waste Pyrolysis Plant

-

Casement Windows & Doors

Casement Windows & Doors

-

Pyrolysis Oil Distillation Plant

Pyrolysis Oil Distillation Plant

-

SCE Series (Dual Mast)

SCE Series (Dual Mast)

-

Casement Windows & Doors

Casement Windows & Doors

-

Continuous Waste Pyrolysis Plant

Continuous Waste Pyrolysis Plant

-

Medical Waste Processing Equipment

Medical Waste Processing Equipment

Hot Products