Cut to Length Line

Description of Cut to Length Line

The cut to length line is specially designed for light pole production and performs uncoiling, leveling, cutting, scrape edge slitting and taper slitting processes. The finished product of the line is a trapezium plate.

It can finish uncoiling, leveling, cross cutting, edge trimming, taper slitting all in one continuous operation.

The slitting line is controlled by a PLC system with a digital display. The line is simply for operation and has high efficiency. With hydraulic system, it is functional, economical and practical.

Features of Cut to Length Line

Edge trimming without rounded edges.

Scrap reduction and material optimization.

The processed sheet is flattened without internal mechanical stress.

Two workers required to operate the machines.

Productivity: 1 trapezium plate per minute.

Technical Parameters of Cut to Length Line

| Model | PCTLT- 2-6x1600 |

| Thickness of plate | 2.0mm-6.0mm |

| Coil material | Q235A hot rolled mild steel |

| Width of material | 800-1600mm |

| Weight of steel coil | Max 15 tons |

| Inner diameter of steel coil | Φ500mm-Φ750mm |

| Leveling speed | 5- 15m/min |

| Number of leveling rollers | 13 Nos |

| Leveling rollers diameter | 130mm |

| Length range for scale | 2000 ~ 14000mm |

| Tolerance of cutting length | ±15mm (base on 8m length plate) |

| Main leveler motor power | 45KW |

| Width area for machine | 7000mm |

| Gross weight | About55T |

| Overall sizes | 34000x7000x2200 mm |

Links:https://www.globefindpro.com/products/53403.html

-

Circumferential Welding Lathe

Circumferential Welding Lathe

-

Pole Straightening Machine

Pole Straightening Machine

-

CSP Solar Energy Glass

CSP Solar Energy Glass

-

PALADIN Series 150cc Scooter / Moped

PALADIN Series 150cc Scooter / Moped

-

Automatic Submerged Arc Welding Machine

Automatic Submerged Arc Welding Machine

-

EIVISSA 150cc Scooter / Moped

EIVISSA 150cc Scooter / Moped

-

Bullet Proof Glass / Bullet Resistant Glass

Bullet Proof Glass / Bullet Resistant Glass

-

Multi-Laminated Fire Resistant Glass

Multi-Laminated Fire Resistant Glass

-

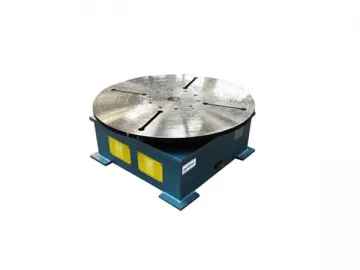

Floor Turntable Positioner

Floor Turntable Positioner

-

Railway Side-Window

Railway Side-Window

-

Tilting Welding Positioner

Tilting Welding Positioner

-

Pneumatic Spot Welder

Pneumatic Spot Welder