High-Speed Paper Cup Forming Machine

The RD-12/22-100A high speed paper cup forming machine features two turn plates, an open intermittent indexing cam mechanism, gear transmission and a longitudinal axis structure. The entire paper cup forming machine features an automatic lubrication system, allowing all mechanical parts to run smoothly. The cup side dealing is done by a Switzerland Leister Heater in order to ensure the side sealing stability, and the bottom sealing is carried out using a Switzerland Leister hot air device. Curling of the cup top is carried out in two steps: rotary curling and heat configuration. This ensures the curling process is stable and gives the cup a better appearance. The cup forming machine comes with a PLC control system, sensor failure detection, and improves overall operation safety while simultaneously reducing labor costs. This paper cup production machine carries out paper feeding, side sealing, cup bottom punching and feeding, heating, knurling, cup-top curling, and stacking, making it an ideal piece of equipment for paper cup production lines.

The characteristic of the machine

1.High speed paper cup forming machine comes with two turnplate, open intermittent cam mechanism and gear transmission, longitudinal axis structures. The cam is made in Korea.

2. The whole machine adopts automatic lubrication system, which makes all mechanical parts working much more smoothly.

3. Bottom sealing by hot air devices, so that the machine is efficient, the hot air device is imported from Switzerland.

4.The new machine with higher working speed (100pcs/min) , so there is extra Switzerland Leister hot air device for the side sealing, so side sealing is done by both Hot air and Ultrasonic.

5. Cup side sealing by ultrasonic.

6. Cup top curling has two steps, rotary curling and heating figuration, which makes the curling more stable and with better appearance (round and smooth).

7. The machine comes with PLC control system, sensor failure detecting and it stops working automatically if the machine has any problem, it can greatly improve operation safety and reducing labor cost. THE PLC, touch screen, Invertor, temperature controller and sensor is made in JAPAN.

8. All bearing of the machine is made in Japan (NSK brand), and the vacuum generator is made in Japan (SMC brand).

9. More efficient and higher performance.

10. It is easy to make cups with different sizes by changing moulds.

11. With automatic cup delivery system and counter.

12. The machine can be equipped with an optional automatic packing machine, which can pack up to 400 paper cups per minute.

Technical Parameters

| Cup size | 6-12oz, 12oz-22oz |

| Paper material | 180-380gsm single or double pe coated paper |

| Speed | 80-100pcs/min |

| Max. cup dimensions | Top diameter: 105mm Cup height: 170mm Bottom diameter: 80mm |

| Min. cup dimensions | Top diameter: 55mm Cup height: 60mm Bottom diameter: 45mm |

| Power supply | 380V or 220V, 50HZ, 3PH |

| Total power | 10KW |

| Compressor air | 0.4m3/min |

| Weight | 3100kgs |

| Overall dimensions | 2.73M*1.66M*1.8M |

Paper Cup Samples

Links:https://www.globefindpro.com/products/53453.html

-

PALADIN Series 125cc Scooter / Moped

PALADIN Series 125cc Scooter / Moped

-

Linking Conveyor

Linking Conveyor

-

LED Bulbs and Tubes Aging Line

LED Bulbs and Tubes Aging Line

-

Wave Soldering Machine, GSD-WD300C

Wave Soldering Machine, GSD-WD300C

-

PCB Workstation Belt Conveyor (18-25 meters)

PCB Workstation Belt Conveyor (18-25 meters)

-

Paper Cup Packaging Machine

Paper Cup Packaging Machine

-

Linking Conveyor (Working Light Installable)

Linking Conveyor (Working Light Installable)

-

Manual Insertion Conveyor

Manual Insertion Conveyor

-

Component Insertion Machine

Component Insertion Machine

-

Universal Paper Cup Forming Machine

Universal Paper Cup Forming Machine

-

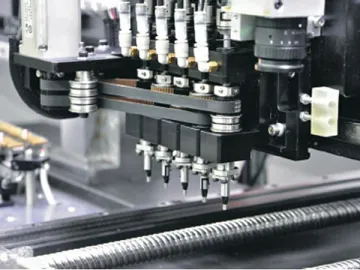

High Speed LED Mounter, GSD-TP12

High Speed LED Mounter, GSD-TP12

-

Wave Solder Outfeed Conveyor

Wave Solder Outfeed Conveyor