Fully Automatic Paper Cup Production Machine

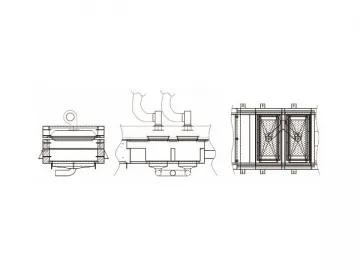

RD-LB120-3600A automatic paper cup forming machine is our latest machine, which is made base on our manufacturing experience and advanced technology from oversea countries, it is a pioneer equipment in China. The machine comes with rectangle tube and channel steel welding structure, which is stronger and small deformation, automatic lubrication system, which makes all mechanical parts working much more smoothly. The cup bottom adopts the stretching die which make the bottom sealing quality better and less leaking percentage. It has PLC control, sensor failure detecting system, cup bottom paper feeding controlled by servo motor, bottom paper will be delivered when cup tube comes, otherwise no bottom paper delivery. The machine has safety guard to protect the people working safely, it is the best choice for making paper cups. It has working speed 65pcs/min, with Ultrasonic sealing, automatic lubrication, PLC control and touch screen, safety guard, with cam system instead of chains, 2 gear boxes included(125-8 and 80 model).

Details

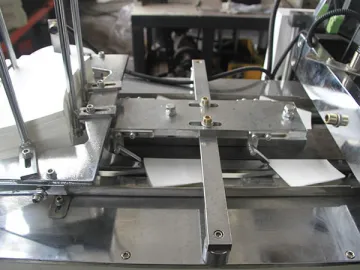

This machine is one of Ruida’s patented products. Welded into a rectangular tube and channel steel, the fully automatic paper cup forming machine features high strength and very little deformation.

1. The machine sprays the lubricant, significantly reducing the wear on machine parts.

2. The stretched and stamped bottom has a better effect and lowers the chances of the cup leaking.

3. The production process is under PLC control, and the cup forming machine can make 55-65 cups in sizes ranging from 6 to 22 oz.

Technical Parameters

| Paper cup size | 4-12oz, 6-22OZ |

| Working speed | 45-65pc/min |

| Paper cup top diameter | 45mm-85mm, 55mm-105mm |

| Paper cup bottom diameter | 35mm-62mm, 45mm-80mm |

| Paper cup height | 35mm-125mm, 60mm-120mm |

| Raw material | 1PE and 2PE coated paper, 180-350gsm |

| General power | 380V/220V, 3 phases, 9KW |

| Air consumption | 0.4cbm/min |

| Gross weight | 2500KGS |

| Packing dimension | 2730mm*1460mm*1800mm |

Transmission part gears

3 thick guide posts are mounted on each side to enhance the stability.

Links:https://www.globefindpro.com/products/53471.html

-

Chip Mounter, GSD-TP832

Chip Mounter, GSD-TP832

-

Chip Mounter, SM482

Chip Mounter, SM482

-

Semi-auto Stencil Printer GSD-YS600

Semi-auto Stencil Printer GSD-YS600

-

Lead Free Reflow Oven, GSD-L12

Lead Free Reflow Oven, GSD-L12

-

Fully Automatic Solder Paste Screen Printer, GSD-PM1200L

Fully Automatic Solder Paste Screen Printer, GSD-PM1200L

-

Lead Free Reflow Oven, GSD-L8

Lead Free Reflow Oven, GSD-L8

-

ZYA1 150cc Scooter / Moped

ZYA1 150cc Scooter / Moped

-

Chip Mounter, GSD-TP810

Chip Mounter, GSD-TP810

-

PCB Magazine Loader

PCB Magazine Loader

-

Chip Component Taping Machine

Chip Component Taping Machine

-

Automatic Paper Cup Handle Fixing Machine

Automatic Paper Cup Handle Fixing Machine

-

Automatic Punching and Die Cutting Machine RD-CQ-850

Automatic Punching and Die Cutting Machine RD-CQ-850