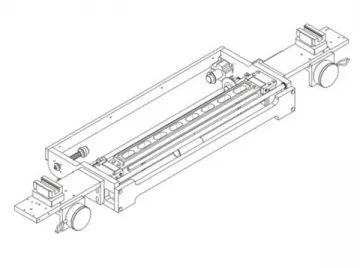

Welding Machine Assembly Line (Fully Automatic)

Welding Machine Assembly Line, Automatic Assembly Line for Welding Equipment, Assembly System for Welding Machine

Fully Automatic Assembly Line for Welding Machine, 15 Meters

Dimensions of assembly line: 15(L) ×1.95 (W) × 1.95 (H) m

Dimensions of work table: 500(L) × 500(W) × 20(T) mm

Hoisting System

1. DPG 60W motor

2. Cylinder 2-position 5-way solenoid valve

3. OMRON limit switch

Transmission System

1. DPG 60W motor

2. OMRON limit switch SKK sensor

Dimensions of assembly line: 20(L) ×1.95 (W) × 1.88 (H) m

Work table

Covered with green anti-static rubber, with dimensions of 500(L) × 500(W) × 20(T) mm

Hoisting System

1. DPG 60W motor

2. Cylinder 2-position 5-way solenoid valve

3. OMRON limit switch

Transmission System

1. DPG 60W motor

2. OMRON limit switch SKK sensor

Machine Structure

1. The support makes use of 50mm× 50mm× 2.0mm steel square tubes. The height of work table is 740±20 mm.

2. Both sides of the assembly line utilize high strength 100× 118 mm aluminum material is used.

Worktable

The work table is coated with anti-static rubber and covered with T-shaped binding tape at corners. It’s 700mm long, 600mm wide and 25mm thick.

Hoisting System

1. Cylinder 2-position 5-way solenoid valve

2. OMRON limit switch

3. Pulley

Assembly System

1. The bracket is made using 40mm×40mm×2.0mm. The work table is 740±20 mm high. The exterior frame is produced from steel.

2. 28W energy saving tubes are used. The tube bracket is made from 25×50 mm steel tubes.

3. Each work position in the power system is outfitted with two-port outlet.

4. Pulley

Test System Weld System

1. The bracket is made using 40mm×40mm×2.0mm. The work table is 740±20 mm high.

2. External frame utilizes 25×130 mm aluminum material.

3. Power for test system

4. Pulley

Package System

1. The bracket is made using 40mm×40mm×2.0mm. The work table is 740±20 mm high.

2. 28W energy saving tubes are used. The tube bracket is made from 25×50 mm steel tubes.

3. External frame utilizes top quality steel.

4. Pulley

Major Parts of Fully Automatic Assembly Line for Welding Machine

Drive System

1. Yong Kun 2HP horizontal motor, 1: 120 gearbox

2. Working speed: 6 meters/min

3. RF2060 high-speed chain

Electric System

1. Mitsubishi PLC

2. Mitsubishi air switch

3. OMRON relay

Work Table

The table makes use of 20 mm plates and is covered with anti-static rubber and T-shape binding tape.

Barrier

The barrier is controlled by a foot switch.

Others

1. The support makes use of 50mm× 50mm× 2.0mm steel square tubes. The height of work table is 740±20 mm.

2. Both sides of the assembly line utilize high strength 100× 118 mm aluminum material is used.

3. T5 18W LED tubes are applied for lighting. The light bracket is produced from 20×50 mm steel tubes.

4. The power system is installed with a socket every 1.2 meters.

5. 40SM and 20PH connectors are implemented.

6. Aluminum materials and A4 acrylic board are applied in the work table.

7. 28×35mm aluminum material is used for the guide rail.

Currently, we are able to offer fully automatic assembly line for welding machines of 15 meters, 20 meters and 48 meters.

Links:https://www.globefindpro.com/products/53517.html

-

Fully Automatic Solder Paste Screen Printer, GSD-PM400A

Fully Automatic Solder Paste Screen Printer, GSD-PM400A

-

Cocamide MEA (CMEA)

Cocamide MEA (CMEA)

-

Automatic Insertion Conveyor

Automatic Insertion Conveyor

-

Wave Soldering Machine, GSD-WD350CE

Wave Soldering Machine, GSD-WD350CE

-

Lead Free Reflow Oven, GSD-M8NE

Lead Free Reflow Oven, GSD-M8NE

-

Wave Solder Pot

Wave Solder Pot

-

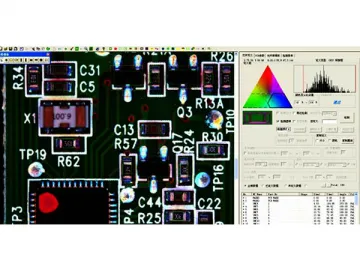

AOI Inspection Machine, GSD-600AOI

AOI Inspection Machine, GSD-600AOI

-

Cocamidopropylamine Oxide (CAO)

Cocamidopropylamine Oxide (CAO)

-

Ethylene Glycol Distearate (EGDS)

Ethylene Glycol Distearate (EGDS)

-

PCB Traverser / Shuttle Conveyor

PCB Traverser / Shuttle Conveyor

-

Solder Paste Mixer

Solder Paste Mixer

-

Double Wave Soldering Machine, GSD-WD300T

Double Wave Soldering Machine, GSD-WD300T