Automatic PCB Test Line (for Mobile Phone)

PCB Test Line for Cell Phones, Automatic PCB Test System, PCB Inspection System

Brief Introduction

This automatic PCB test line is designed with several automatic PCB testers, integrating robot technology and flexible design. It satisfies different requirements for the inspection of circuit boards. By this automatic PCB test line for mobile phone, user can conduct inspection and examination on cell phones and wireless modules, adjust parameters, test WIFI GPS function and more.

This automatic PCB test system is also known for its automatic feeding, conveying, screening out unqualified products, etc. By using a robot, the PCB inspection system effectively cuts cost and improves production. At the same time, this automatic PCB test line for mobile phone is compatible with various tests of different products, realizing high universality.

Working Process

Firstly of all, according to the positioning device, the robot captures the PCB and sends it to the testing box. Secondly, after receiving the circuit board, the testing box automatically conducts series of exams. Thirdly, when the primary test is finished, the robot will then put the board into another testing box, which will finally get rid of unqualified products and send it to the defective product belt.

Main Advantages

1. Automatic Feeding Device

The special piling design contributes to continuous and smooth feeding. Plus, an independent positioning device is equipped.

2. Automatic Discharging Device

When the quantity of finished products accumulates to a certain value, the device will automatically discharge. Meanwhile, the alarming system will give a warning while no materials or materials overloaded. A wheel is also outfitted to simplify the products moving work.

3. Unqualified Product Rejection

A photoelectric sensor is used to detect defective products, which will then be transferred by variable frequency motor.

4. Short Jig Changing Time

Through hard working and innovation, we greatly cut the jig changing time to 20 seconds. In addition, the robot automatically makes machine adjustment to ensure the machine runs at its optimum.

Technical Parameters

| Machine | Automatic PCB test line for mobile phone | ||

| Ports | Dual-ports | ||

| 8 ports (8*2) | 12 ports (12*2) | ||

| Dimensions | 2500*2200*2000 mm | ||

| Functional circuit test | DL, SN, BT, FT, WBG | DL, SN | |

| Max. size of PCBA | 140*68mm | ||

| Standard hardware configurations | EPSON LS6 mechanical arm | ● | ● |

| RC90 controller | ● | ● | |

| Automatic feeding and discharging device | ● | ● | |

| Computer display | ● | ● | |

| Nozzles ×4 | ● | ● | |

| Top-mounted camera×1 | ● | ● | |

| Standard software configurations | Software controller | ● | ● |

| Software package | ● | ● | |

| Recognizing system | ● | ● | |

| Flexible distributing system | ● | ● | |

| Automatic position calibration system | ● | ● | |

| Optional devices | Shielding box | ○ | ╳ |

| Top-mounted camera | ○ | ○ | |

| Bottom-mounted camera | ○ | ○ | |

| Transferring unit with 2 channels and 3 working positions | ○ | ○ | |

| Transferring unit with 4 channels and 3 working positions | ○ | ○ | |

| Transferring unit | ○ | ○ | |

| Transferring unit with 20 pairs of working positions | ○ | ○ | |

| Computer display of testing machine | ○ | ○ | |

| Notes: ● Required ○ Optional ╳ Unavailable | |||

Links:https://www.globefindpro.com/products/53534.html

-

Stencil Drying Rack

Stencil Drying Rack

-

Cetrimonium Chloride (CTAC/1631)

Cetrimonium Chloride (CTAC/1631)

-

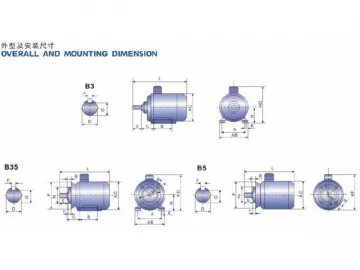

Electric Motor, Y2 Series

Electric Motor, Y2 Series

-

Electric Motor, MS Series

Electric Motor, MS Series

-

Centrifugal Pump, SCM2 Series

Centrifugal Pump, SCM2 Series

-

Centrifugal Pump, HF Series

Centrifugal Pump, HF Series

-

Lauramidopropyl Betaine (LAB)

Lauramidopropyl Betaine (LAB)

-

Dodecyl Trimethyl Ammonium Chloride (1231)

Dodecyl Trimethyl Ammonium Chloride (1231)

-

Loose Radial Lead Cutting Machine

Loose Radial Lead Cutting Machine

-

Chip Mounter, SM471

Chip Mounter, SM471

-

Wave Solder Input Conveyor

Wave Solder Input Conveyor

-

Double Wave Soldering Machine, GSD-WD300R

Double Wave Soldering Machine, GSD-WD300R