KCB Series Fuel Transfer Pump, Diesel Transfer Pump

Electric Diesel Pump, Fuel Pump, Oil Transfer Pump, Petrol Fuel Transfer Pump, Electric Fuel Transfer Pump, Fuel Transfer System

Technical Parameters

Model: 18.3-9600

Flow rate: 1.1 m3/h-570 m3/h

Rotational speed: 740 r/min-1440 r/min

Discharge pressure: 0.28Mpa-1.45Mpa

Net positive suction head: 5m-8m

Motor power: 1.5KW-250KW

Application Scopes of Fuel Transfer Pump

This type of oil transfer pump is ideal for transferring heavy oil, diesel, machine oil and vegetable oil that is non-corrosive, contains no impurities or fibers, as well as has a viscosity less than 150mm2/s and temperature lower than 120℃.

The fuel transfer system is most often used in such industries as petroleum, metallurgy, mining and power stations for oil transfer, pressure boost, injection and circulation.

Description of Fuel Transfer Pump

In this industrial fuel pump, all components have been well designed and handled, and can take advantage of transferred media as lubricating agent. To get higher strength and rigidity, the gear has undergone heat treatment and coordinated closely with the shaft. The well designed oil drain slot and oil return slot provide minimum torque strength for gear, which in turns brings less load and abrasion for bearing and high working efficiency. If the media are highly corrosive, acid- and alkali-resistant materials are available upon request. When it comes to combustive and explosive media, copper-made and nonmetal-made parts for the fuel transfer pumps are available.

Major Configurations of Fuel Transfer Pump

The gear type diesel transfer pump is composed of pump body, pump cover, gear, shaft, bearing, safety valve and sealing ring.

As for the pump body and cover, high precision and fine quality have been realized due to the use of CNC machine.

As an overload protection device, the safety valve is set to provide 1.5 times pressure of pump and can also have proper adjustment according to actual working demands.

Involute gears are applied.

Processed from advanced numerical control machinery, the main shaft enjoys a high degree of precision.

For sealing, two sealing methods are available. One is mechanical sealing, which is appropriate for transferring lubricous media that contains no impurities. Its biggest advantage is no leakage. The other one is called packing sealing. It features elasticity, self-lubrication, abrasion resistance and high chemical stability. The sealing ring can be chosen according to actual working conditions and customer requirements.

See how we produce the fuel transfer pumps, .

Since our inception in 1998, Life has been working on the design and manufacture of industrial transfer pumps. With 18 years of technical expertise and practical experience, we are able to make a great number of premium quality transfer pumps which include: fuel transfer pumps, lube oil pumps, screw pumps, etc. In addition, tailor made oil transfer pumps are welcomed. Up to now, we have realized an annual production of 100,000 oil pumps, many of which have been sold to over 20 countries and regions, like the Middle East, U.S., Europe, etc.

Life Pumps at Working Sites

Pump for oil transmission

Pump for oil transmission

Links:https://www.globefindpro.com/products/53579.html

-

Precipitated Silica for Tires and Rubber Products

Precipitated Silica for Tires and Rubber Products

-

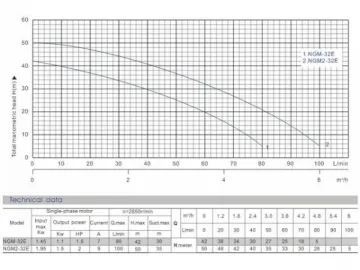

Deep Well Pump, NGM Series

Deep Well Pump, NGM Series

-

NYP Series Rotary Lobe Pump, Viscous Fluid Pump

NYP Series Rotary Lobe Pump, Viscous Fluid Pump

-

Precipitated Silica for Coatings

Precipitated Silica for Coatings

-

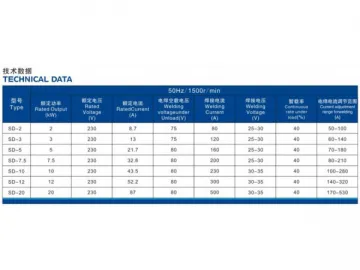

Generating and Welding Dual-Use Alternator/Generator

Generating and Welding Dual-Use Alternator/Generator

-

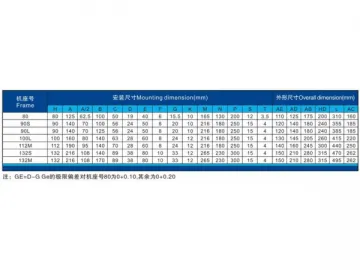

EMA Series (IE3)

EMA Series (IE3)

-

Precipitated Silica for Silicon Rubber

Precipitated Silica for Silicon Rubber

-

Horizontal Multistage Centrifugal Pump, MH1300 Series

Horizontal Multistage Centrifugal Pump, MH1300 Series

-

Electric Motor, YS/YU/YC/YY Series

Electric Motor, YS/YU/YC/YY Series

-

Electric Motor, YC Series

Electric Motor, YC Series

-

Oil Transfer Pump

Oil Transfer Pump

-

Precipitated Silica for Animal Nutrition

Precipitated Silica for Animal Nutrition