G Series Single Screw Pump, Viscous Fluid Pump

Transfer Pump for highly viscous Liquid, High Viscosity Pump for thick Fluids, Pumping Viscous Fluid, Heavy Oil Pump

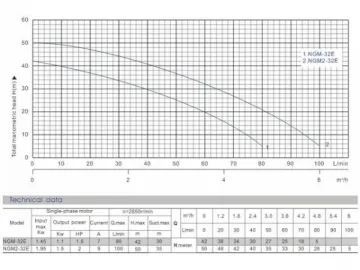

Technical Parameters of Viscous Fluid Pump

Model: G20-1- G135-1

Pressure: 0.6Mpa-1.2Mpa

Flow: 0.8m3-150m3

Motor power: 0.75KW- 37KW

Description of Single Screw Pump

This helical rotor pump, also known as viscous fluid pump, is our newly developed product. As main working parts, rotor and stator produce separated and sealed chambers, in which transferred fluid is moved in a constant speed. In addition to this, no eddy or fluctuation will be caused due to a low flow speed, stable pressure and constant volume. If the media are highly corrosive, acid- and alkali-resistant components are available on request. When it comes to combustive and explosive materials, copper-made and nonmetal-made parts can be chosen.

Application Scopes of Single Screw Pump

This transfer pump for highly viscous liquid provides an output pressure of 0.6 Mpa, a water head of 60m and self-suction height of 6m, suitable for fluids with a temperature lower than 80 ℃ (150℃ can also be customized for special requirements). It's superior to commonly-used pumps while transferring high viscosity fluids or media with particles and fibers, thanks to the highly elastic and efficient stators.

Grease

Syrup

Heavy oil

Outstanding Characteristics of Single Screw Pump

This type of viscous fluid pump transfers fluids in a constant speed. Low flow speed, stable pressure and invariable volume leads to no eddy or fluctuation. The flow speed is proportional to rotational speed, enabling stable and efficient work.

Other devices can also be utilized for transmission, such as coupler, adjustable-speed motor, transmission belt, gearbox and so forth. Pumps provided by Life are known for fewer components, compact structure, small volume, easy to install, convenient to maintain and more. Both rotor and stator are wearing parts and simply easy to install.

Some Configurations of High Viscosity Pump

The single screw pump body possesses fine quality and high precision due to modern process and advanced precise-casting techniques.

Two sealing methods are available: mechanical sealing and packing sealing. The former method is appropriate to transfer lubricant and impurity-free liquids, with no leakage. The latter provides excellent elasticity, self-lubrication, abrasion resistance and high chemical stability. Customers can choose in accordance with actual requirements.

Stator is a vital part but also easily-worn part in screw pump. The degree of precision and selection of raw materials directly decides its service life.

Please click here for .

Since our inception in 1998, Life has been working on the design and manufacture of industrial transfer pumps. With 18 years of technical expertise and practical experience, we are able to make a great number of premium quality transfer pumps which include: fuel transfer pumps, lube oil pumps, screw pumps, etc. In addition, tailor made oil transfer pumps are welcomed. Up to now, we have realized an annual production of 100,000 oil pumps, many of which have been sold to over 20 countries and regions, like the Middle East, U.S., Europe, etc.

Oil Pumping Applications

Links:https://www.globefindpro.com/products/53587.html

-

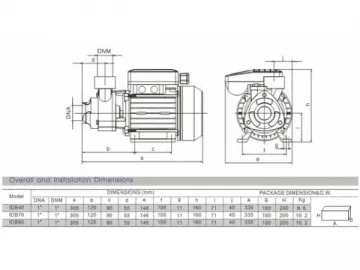

Peripheral Pump, IDB Series

Peripheral Pump, IDB Series

-

Deep Well Pump, SP Series

Deep Well Pump, SP Series

-

2-5.8kw Gasoline Generator Set (HONDA Engine)

2-5.8kw Gasoline Generator Set (HONDA Engine)

-

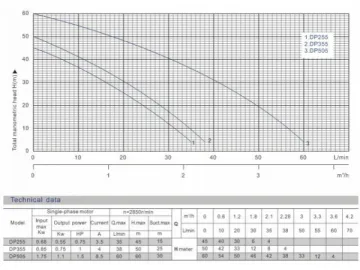

Deep Well Pump, DP Series

Deep Well Pump, DP Series

-

Electric Motor, YLK Series

Electric Motor, YLK Series

-

High Disperse Silica

High Disperse Silica

-

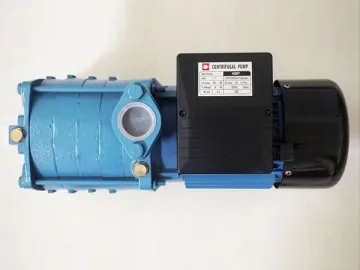

Horizontal Multistage Centrifugal Pump, HMP Series

Horizontal Multistage Centrifugal Pump, HMP Series

-

EMA Series (IE3)

EMA Series (IE3)

-

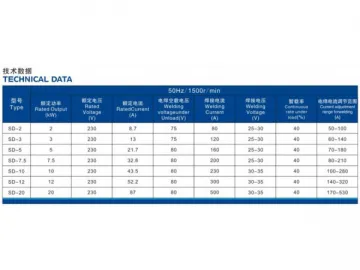

Generating and Welding Dual-Use Alternator/Generator

Generating and Welding Dual-Use Alternator/Generator

-

Precipitated Silica for Coatings

Precipitated Silica for Coatings

-

NYP Series Rotary Lobe Pump, Viscous Fluid Pump

NYP Series Rotary Lobe Pump, Viscous Fluid Pump

-

Deep Well Pump, NGM Series

Deep Well Pump, NGM Series