KCB Series Lubrication Pump, Lube Oil Pump

Lubricant Transfer Pump, Oil Lubricator, Automatic Lubrication Pump, Electric Pumps for Grease Transfer, Lube Oil Pumping Applications, Electric Grease Transfer Pump

Technical Data of Lube Oil Pump

Model: 18.3-9600

Flow rate: 1.1 m3/h-570 m3/h

Rotational speed: 740 r/min-1440 r/min

Discharge pressure: 0.28 Mpa-1.45 Mpa

Net positive suction head: 5m-8m

Motor power: 1.5KW-250KW

Applicable Scopes of Lubrication Pump

This lubricating pump is intended for such media like heavy oil, diesel, machine oil, vegetable oil and other similar liquids. The media should be non-corrosive, contain no impurities and have a viscosity less than 150mm2/s and a temperature lower than 120℃.

Applied for pressure boost, oil transmission, injection and circulation, this grease pump is widely used in petroleum, metallurgy, mining and power industry.

Description of Lubrication Pump

The KCB series lubrication pump is composed of gear, shaft, pump body, safety valve and sealing ring. All parts of the lube oip pump have been well designed and processed in order for high rigidity and strength. As for the gear, it has gone through thermal treatment and achieves a close coordination with the shaft. Also, the oil slot is intended to fix oil drain and oil return problems, therefore guaranteeing minimum torque strength for gear, less load and abrasion for bearing and much higher transferring efficiency. If the media are highly corrosive, acid- and alkali-resistant components are available on request. When it comes to combustive and explosive lube oils, copper-made and nonmetal-made parts are accessible.

Characteristics of Lubrication Pump

Parts of this lube oil pump include pump body, pump cover, gear, shaft, safety valve and sealing ring.

The lubricant transfer pump and cover has been finish casted and then processed by CNC machine, providing high precision and better quality.

Considering overload problems, a safety valve is installed. The backflow pressure of this valve is 1.5 times that of the pump. Plus, within the range of pressure discharge, the pressure can also be adjusted upon request.

Involute gears are utilized.

The main shaft for the oil lubricator is processed by newly developed CNC machine and enjoys high precision.

For sealing, two sealing methods are provided. One is mechanical sealing, which is appropriate for transferring lubricous media that contains no particles or fibers. Its biggest advantage is no leakage. The other one is called packing sealing, which is featured by great elasticity, self-lubrication, abrasion resistance and high chemical stability. The sealing ring can be chosen according to actual working conditions and customer requirements.

Click here for.

Since our inception in 1998, Life has been working on the design and manufacture of industrial transfer pumps. With 18 years of technical expertise and practical experience, we are able to make a great number of premium quality transfer pumps which include: fuel transfer pumps, lube oil pumps, screw pumps, etc. In addition, tailor made oil transfer pumps are welcomed. Up to now, we have realized an annual production of 100,000 oil pumps, many of which have been sold to over 20 countries and regions, like the Middle East, U.S., Europe, etc.

Lube Oil Pumping Applications

Grease Pumps for transferring oil

Grease Pumps for transferring oil

Links:https://www.globefindpro.com/products/53594.html

-

Water Pump Parts

Water Pump Parts

-

EM Series (IE2)

EM Series (IE2)

-

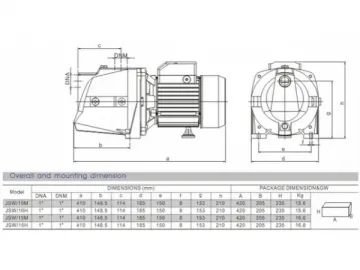

Self-Priming Jet Pump, JA Series

Self-Priming Jet Pump, JA Series

-

Self-Priming Jet Pump, JSW Series

Self-Priming Jet Pump, JSW Series

-

H beam horizontal production line

H beam horizontal production line

-

H Steel Shot Blasting and Cleaning Machine

H Steel Shot Blasting and Cleaning Machine

-

High Disperse Silica

High Disperse Silica

-

Electric Motor, YLK Series

Electric Motor, YLK Series

-

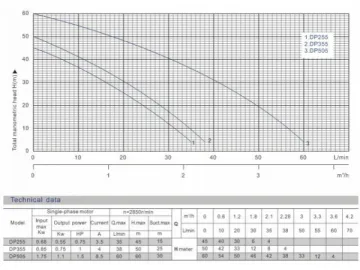

Deep Well Pump, DP Series

Deep Well Pump, DP Series

-

2-5.8kw Gasoline Generator Set (HONDA Engine)

2-5.8kw Gasoline Generator Set (HONDA Engine)

-

Deep Well Pump, SP Series

Deep Well Pump, SP Series

-

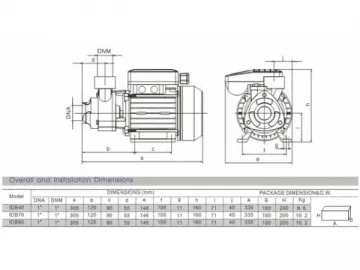

Peripheral Pump, IDB Series

Peripheral Pump, IDB Series