CNC Drilling Machine

The CNC drilling machine is designed with CNC system. The movement of X axis and Y axis is achieved through AC servo control and Z axis can implements hydraulic automatic feed. Thus, the equipment can realize quick positioning and drilling and has been widely used for drilling process for connecting plate of steel construction and various kinds of plate parts. Its main components are machine bed, mobile gantry frame, drilling head, switchable worktable, electric control system, hydraulic system, cooling system and chip conveyer.

Technical Parameters

| Model | ZP1650 | ZPZ200 |

| Max. Drilling Diameter | φ50mm | 60φmm |

| Max. Size of Work Piece | 1650×1000×80mm | 2000×1500×80mm |

| Spindle Speed | 130-400r/min( Poleless Speed-adjusting) | 130-400r/min |

| Feed Mode of Spindle | Hydraulic Control | Screw Mandrel Control |

| Quantity of Mobile Worktable | 2 | 2 |

| Quantity of Work Piece to Be Clamped at the Same Time | 4 Groups | 4 Groups |

| Working Mode for Clamping | Hydraulic Control | Hydraulic Control |

| Fast-moving Speed of X and Y Axes | 12m/min | 12m/min |

Zhouxiang Group is a professional CNC drilling machine manufacturer based in China. We provide a vast array of products, including high speed arc spray equipment, IGBT inverter DC manual arc welder, back welding machine and more.

Links:https://www.globefindpro.com/products/53606.html

-

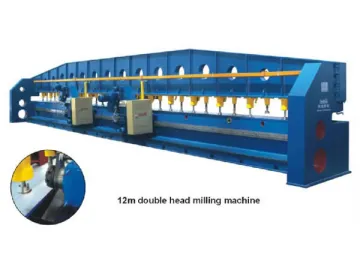

Edge Milling Machine

Edge Milling Machine

-

H beam assembling welding straightening integral machine

H beam assembling welding straightening integral machine

-

Heavy Duty Overturning Machine, Conveying Machine

Heavy Duty Overturning Machine, Conveying Machine

-

SN, 3G Series Triple Screw Pump, Fuel Transfer Pump

SN, 3G Series Triple Screw Pump, Fuel Transfer Pump

-

H Steel Flange Straightening Machine

H Steel Flange Straightening Machine

-

Cantilever Welding Machine

Cantilever Welding Machine

-

Metal Cans (Powder Packaging)

Metal Cans (Powder Packaging)

-

Metal Containers (Hardeners Packaging)

Metal Containers (Hardeners Packaging)

-

Cone Top Cans

Cone Top Cans

-

H Steel Shot Blasting and Cleaning Machine

H Steel Shot Blasting and Cleaning Machine

-

H beam horizontal production line

H beam horizontal production line

-

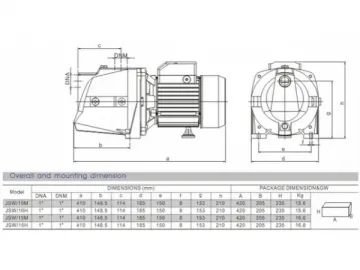

Self-Priming Jet Pump, JSW Series

Self-Priming Jet Pump, JSW Series