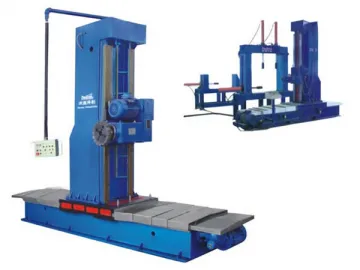

CNC Face Milling Machine

The CNC face milling machine is constructed with milling head, lifting column, worktable, machine bed, mechanical feed system, electric control system, CNC system, guide rail protective device and cutting tool. It is mainly used to complete the end face milling process of welded or rolled H steel or box beam.

Featuring convenient operation, simple structure and rapid adjustment, the CNC face milling machine is the indispensable equipment of professional welded steel manufacturer. It can mill the work piece with the size of end face ranging from 300×200mm to 1200×1500mm. It can also mill the side face of H steel or box beam. The feed of slipway and lifting of milling head are accomplished through Guangzhou CNC DA98A driving servo motor.

The DA98A AC servo system is Chinese first generation digital AC servo system, which takes usage of the newest TMS320F2407A digital signal processor (DSP) of American IT Company, complex programmable logic device (CPLD) and Mitsubishi intelligent power module. With the merits of high integration level, small volume, perfect protection and good reliability, the AC servo system adopts optimal proportion integration differentiation (PID) algorithm to achieve pulse width modulation (PWM) control. The performance of our product with the DA98A AC servo system has reached the level of the same product abroad.

We are an experienced CNC face milling machine manufacturer in China. In addition to box beam production line, we also provide heavy steel production line, shot blasting equipment, rolling machine, CNC cutting machine, and more.

Links:https://www.globefindpro.com/products/53624.html

-

Metal Cans (For Syrup, Ketchup, Jam, Honey, etc)

Metal Cans (For Syrup, Ketchup, Jam, Honey, etc)

-

Rectangular Cans

Rectangular Cans

-

YCB Series Fuel Transfer Pump, Diesel Transfer Pump

YCB Series Fuel Transfer Pump, Diesel Transfer Pump

-

Metal Containers (Gasoline Packaging)

Metal Containers (Gasoline Packaging)

-

Metal Containers (Paints Packaging)

Metal Containers (Paints Packaging)

-

Metal Cans (Tea Leaves Packaging)

Metal Cans (Tea Leaves Packaging)

-

180º Hydraulic Overturning Machine

180º Hydraulic Overturning Machine

-

Heavy Duty Steel Vertical Assembly Machine

Heavy Duty Steel Vertical Assembly Machine

-

SN, 3G Series Triple Screw Pump, Lubricant Pump

SN, 3G Series Triple Screw Pump, Lubricant Pump

-

Irregular Cans

Irregular Cans

-

H-Type Steel Automatic Welding Machine

H-Type Steel Automatic Welding Machine

-

Face Milling Machine

Face Milling Machine