Vacuum Packaging Machine

Main Specification of Vacuum Packing Machine

1.Vacuum packing machine remove the air from the package at the same time sealing it, delivering the ultimate in protection while extending the distribution life and maintaining product integrity.

2.Vacuum packing machine commonly use the vacuum bags or barrier pouches. These barrier bags provide a barrier against the atmosphere and moisture. The bags are placed in the chamber; the desired amount of air is extracted from the vacuum bag and then sealed.

3.All of Vacuum packing machine are made from stainless steel and are available in a variety of sizes and configurations such as the option of gas flushing kits.

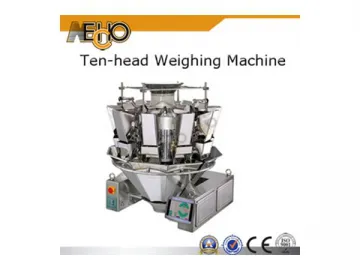

4.The measurement device can adopt multi-head weigher and other device.

5.The main packing machine can adopt automatic rotary packing machine or others type model.

6.We also provide customize made for large volume or bag packing.

| Model | MR6/8-120 |

| Bag size range | 55-120mm(W), 65-130mm(L) |

| Number of degrees | 40-60per/min(real speed should depend on the packing material and bag size |

| Power | 2KW |

| Vacuum Pump | Import kind |

| Operation | Touch screen |

| Drive type | Servo |

| Fitting | Festo |

| Machine material | Stainless steel |

| Air | 0.6m³/min compressed air should supplied by buyer |

Application of Vacuum Packaging Machine

Vacuum packing machines are used to evacuate the air around perishable goods such as food products like pickles, dried bean curd, chicken feet, fried fish and so on whose extension of shelf life is desired.

It can do automatically measurement, filling, vacuum, sealing and products output.

Product Details

Links:https://www.globefindpro.com/products/53739.html