Rotary Vacuum Filling and Sealing Machine

Machine Features of Rotary Vacuum Filling and Sealing Machine

1. Using high techonlogy such as a micro computer display and a graphic touch panel, the machine can be easily performed operation and maintenance

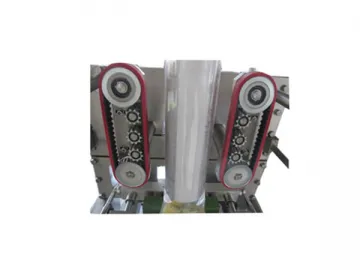

2. Filling machine rotates intermittently to fill the product easily and vacuum machine rotates continuously to enable somooth runing,it means high performance and high durability.

3. All grippers width of filling machine can be adjusted at once by a motor but all grippers in the vacuum chambers are no need to adjust.Main sections are made of stainless steel for excellent durability and hygiene.

4. Water washable all of filling zone and vacuum chambers

5. Weighing machine and liquid&paste doser can be combined with this machine Status in the vacuum chamber can be checked through the transparent plastic vacuum shell lids.

| Model mod | MR8-10ZK |

| Working Position Of machinery | Eight-working station |

| function | Giving bag, coding, opening, fill consolidate1, fill consolidate2, vacuum and sealing, output products |

| Packing materials | Portable bag, zipper bag, hand luggage, edging bag 4 sides, edging bag 3 sides, paper bag |

| Bag size | W:100-200mm L:120~300mm |

| weight | 1200kg |

| Filling volume | 10-1500g(depending on type of product and pouch size) |

| speed | 20-50bags/min(the speed depends on the products status and filling weight) |

| Total power | 220V/380V,3phase,50/60Hz,16kw |

| Compress air requirement | 350N liter/min,6Kg/cm2 |

| Solid species | candy, peanut, green bean, pistachio, crystal candy, brown sugar, cookie, cake, daily commodities, cooked food, pickles, puffed food, etc. |

| Granule species | grain, refined monosodium glutamate, granular drug, capsule, seed, condiment, granulated sugar, chicken essence, melon seeds, nuts, pesticide, fertilizer, feed etc. |

| Powder species | milk powder, coffee powder, food additives, condiments, tapioca powder, coconut powder, pesticide powder, fertilizer granules etc. |

| Liquid species | detergent, fruit juice, miller wine, soy sauce, vinegar, drinks etc. |

| Thick liquid species | detergent, fruit juice, miller wine, soy sauce, vinegar, drinks etc. |

| Materials that can pack in bag real machine. This model has two carousels divided into filling machine of 8stations and clam-shell type vacuum machine with 12 chambers. | |

Product Details

Safety of Rotary Vacuum Filling and Sealing Machine

No bag – no filling- no sealing, machine alarm

Bag opening miss- no filling-no sealing, machine alarm

Machine stop or alarm when the air pressure is abnormal

Error position display at the control panel

Control panel locate on the right side top of the machine.

Outside of the machine and all the parts which touch production all made by stainless steel.

There are several safety doors made by aluminum Profile Frame.

The doors are equipped with safety proximity sensors

Machine surface can be washed by water and brushed by cloth

Links:https://www.globefindpro.com/products/53779.html