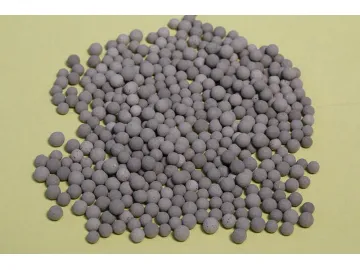

CuO Desulfurizer Activated Alumina

The CuO desulfurizer activated alumina is primarily used for flue gas desulfurization, and features high desulfurization and regeneration kinetic characteristics. It also features an outstanding abrasion resistance, high mechanical strength and a low price.

Chemical composition (wt%)

AL2O3 (wt%): 95

CuO (wt%): 5

Application

This CuO desulfurizer activated alumina is primarily used for flue gas desulfurization.

| Appearance | pewter sphere |

| Sphere size (mm) | Φ2-4 Φ3-5 |

| Bulk density(g/cm3) | 0.70-0.80 |

| Crush strength (N/ sphere) | 80 120 |

| Surface area(m2/g) | 250-300 |

| Total pore volume(cm3/g) | 0.45-0.50 |

| Abrasion loss (wt%) | 0.1 |

Introductions

SOX is one of the main forces behind acid rain, the greenhouse effect and destruction of the ozone layer, with Sox emission in coal-fired power plants a primary source of air pollution. Because of that, flue gas desulfurization is a necessary process. It is generally divided into two categories: dry desulfurization and wet desulfurization.

Dry flue gas desulfurization of reproducible aluminum supported copper oxide goes through the following process: the flue gas flows through the alumina support grains in the reactor, which is set after a low-temperature coal economizer. The Sox in the flue gas then reacts with the CuO supported on aluminum oxide and generates CuSO4 (300℃-500℃), thereby removing the SOx in flue gas. The main reactions are:

CuO + SO2 + 1/2O2→ CuO4

CuO + SO3→ CuO4

Links:https://www.globefindpro.com/products/53834.html