Multihead Weigher

Typical Application

Biscuits and bakery products Cereal Cheese Chocolate & confectionery products Chocolate & confectionery Dried fruit Fish & seafood French Fries Fruit & Vegetables Meat & poultry Meat & poultry Pet food Seeds & nuts Seeds & nuts

Product Details

Storage and assembly workshop in a customer's factory

Features

The multihead weigher is designed to carry out an automatic dosing of a preset weight for transferring products into a packing machine. The number of weighing heads range from 8 to 32, and the weighing hopper volume ranges from 0.5-6 liters. An optional memory hopper is also available. We also supply specific multihead weighing machines for specific applications, and each machine is built using the latest technology available in China.

10.4 inch touch screen, 6 language choices

Standard IP63 protections, IP66, IP69K available upon request.

Stainless steel SUS304 construction

Modular design with a CAN bus electronic structure

HBM (Germany) load cell, and 32 bit DSP

Pulse width mode (PWM) feeder control and automatic feeder control (AFC) functions

Startup and maintenance is easy using a built-in guide menu

Ready for mixing applications

Optional Devices and Functions

| (1) | Dimpled surface | Decrease the contact surface for non-free flow product |

| (2) | Teflon coating, ceramic glaze coating | Decrease contact surface for non-free flow product, or prevent corrosion |

| (3) | PU coating | Reduce impact |

| (4) | Stainless steel SUS316 or special material finishing | Prevent corrosion |

| (5) | Timing hopper | Provide a clear distance for packer sealing, decrease the drop ping distance |

| (6) | Rejecting hopper | Rejecting enforce combination |

| (7) | Manually discharge device | Semi-auto line |

| (8) | Multi out-put device | For multilane packer |

| (9) | Anti-collision device | Reduce breakage rate for fragile products, or increase drop ping speed by giving better sealing distance |

| (10) | Timing hopper for fragile product | Reduce breakage rates for fragile products, or increase drop ping speed by giving better sealing distance |

| (11) | Independent collecting chute | Reduce breakage rates for fragile products, or increase drop ping speed by giving better sealing distance |

| (12) | Customized radial feeder pan | According to product's character by using pans in V-shape, U-shape or other shapes |

| (13) | Fixed flap device | Product feeding control |

| (14) | Pneumatic flap device | Product feeding control |

| (15) | Alarm light | Alarm for insufficient feeding, enforce combination and more |

| (16) | Dispersion feeder for weighing cell | Feeding control for sticky products |

| (17) | Anti-condensation device | Ensures excellent performance even in low temperature or moist environments. |

Specification

| Number of weighing head | Number of memory hopper | Max. volume of single discharge (ml) | Weighing range (g) | Max. discharging speed (WPM) | Number of mixing products | |

| 8-1.5 | 8 | 0 | 1200 | 500 | 55 | 0 |

| 8-2.5 | 8 | 0 | 5000 | 500 | 55 | 0 |

| 8-2.0/3 | 8 | 8 | 2500 | 1000 | 120 | 0 |

| 10-0.5 | 10 | 0 | 750 | 250 | 65 | 0 |

| 10-0.5/3 | 10 | 10 | 750 | 250 | 140 | 0/2 |

| 10-1.5 | 10 | 0 | 4000 | 1500 | 65 | 0 |

| 10-1.5/3 | 10 | 10 | 4000 | 1500 | 140 | 0/2 |

| 10-2.5 | 10 | 0 | 7000 | 3000 | 65 | 0 |

| 10-2.5/3 | 10 | 10 | 7000 | 3000 | 140 | 0/2 |

| 10-4.0 | 10 | 0 | 9000 | 5000 | 60 | 0 |

| 10-4.0/3 | 10 | 10 | 9000 | 5000 | 130 | 0/2 |

| 10-6.0 | 10 | 0 | 15000 | 5000 | 60 | 0 |

| 12-0.5 | 12 | 0 | 750 | 250 | 90 | 0 |

| 12-0.5/3 | 12 | 12 | 750 | 250 | 160 | 0/2/3 |

| 12-2.5 | 12 | 0 | 7000 | 3000 | 90 | 0 |

| 12-2.5/3 | 12 | 12 | 7000 | 3000 | 160 | 0/2/3 |

| 12-4.0 | 12 | 0 | 9000 | 5000 | 140 | 0 |

| 12-6.0 | 12 | 0 | 15000 | 5000 | 70 | 0 |

| 14-0.5 | 14 | 0 | 750 | 250 | 130 | 0 |

| 14-0.5/3 | 14 | 14 | 750 | 250 | 180 | 0/2/3 |

| 14-1.5 | 14 | 0 | 4000 | 1500 | 130 | 0 |

| 14-1.5/3 | 14 | 14 | 4000 | 1500 | 180 | 0/2/3 |

| 14-2.5 | 14 | 0 | 7000 | 3000 | 130 | 0 |

| 14-2.5/3 | 14 | 14 | 7000 | 3000 | 180 | 0/2/3 |

| 14-4.0 | 14 | 0 | 9000 | 5000 | 110 | 0 |

| 14-4.0/3 | 14 | 14 | 9000 | 5000 | 160 | 0/2/3 |

| 14-6.0 | 14 | 0 | 15000 | 5000 | 90 | 0 |

| 16-0.5 | 16 | 0 | 750 | 500 | 140 | 0 |

| 16-0.5/3 | 16 | 16 | 750 | 500 | 240 | 4 |

| 16-1.5 | 16 | 0 | 4000 | 2000 | 140 | 0/2 |

| 16-1.5/3 | 16 | 16 | 4000 | 2000 | 240 | 0/2/4 |

| 16-2.5 | 16 | 0 | 7000 | 3000 | 140 | 0/2 |

| 16-2.5/3 | 16 | 16 | 7000 | 3000 | 240 | 0/2/4 |

| 16-4.0 | 16 | 0 | 9000 | 5000 | 110 | 0/2 |

| 18-0.5 | 18 | 0 | 750 | 500 | 140 | 0/2 |

| 18-0.5/3 | 18 | 18 | 750 | 500 | 240 | 0/2/4 |

| 18-1.5 | 18 | 0 | 4000 | 2000 | 140 | 0/2 |

| 18-1.5/3 | 18 | 18 | 4000 | 2000 | 240 | 0/2/4 |

| 18-2.5 | 18 | 0 | 7000 | 3000 | 140 | 0/2 |

| 18-2.5/3 | 18 | 18 | 7000 | 3000 | 240 | 0/2/4 |

| 20-0.5 | 20 | 0 | 750 | 500 | 140 | 0/2 |

| 20-0.5/3 | 20 | 20 | 750 | 500 | 280 | 0/2/4/5 |

| 20-1.5 | 20 | 0 | 4000 | 2000 | 140 | 0/2 |

| 20-1.5/3 | 20 | 20 | 4000 | 2000 | 280 | 0/2/4/5 |

| 20-2.5 | 20 | 0 | 7000 | 3000 | 140 | 0/2 |

| 20-2.5/3 | 20 | 20 | 7000 | 3000 | 280 | 0/2/4/5 |

| 24-0.5 | 24 | 0 | 750 | 500 | 160 | 0/2/3 |

| 24-0.5/3 | 24 | 24 | 750 | 500 | 320 | 2/3/4/6 |

| 24-2.0 | 24 | 0 | 4000 | 2000 | 160 | 0/2/3 |

| 24-2.0/3 | 24 | 24 | 4000 | 2000 | 320 | 2/3/4/6 |

| 32-0.5/3 | 32 | 32 | 750 | 500 | 480 | 4/5/6/7/8 |

| 32-2.0/3 | 32 | 32 | 4000 | 2000 | 480 | 4/5/6/7/8 |

Customized size is available on request.

Links:https://www.globefindpro.com/products/53867.html

-

Preduster

Preduster

-

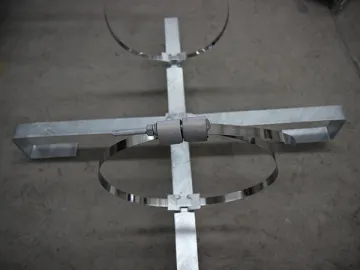

Cross for Storing ADSS Cable

Cross for Storing ADSS Cable

-

Double Action Extrusion Press for Φ90mm-Φ45mm Aluminum Seamless Tube

Double Action Extrusion Press for Φ90mm-Φ45mm Aluminum Seamless Tube

-

Continuous Fryer

Continuous Fryer

-

Double Action Extrusion Press for Φ120mm-Φ65mm Aluminum Seamless Tube

Double Action Extrusion Press for Φ120mm-Φ65mm Aluminum Seamless Tube

-

Seasoning Tumbler

Seasoning Tumbler

-

Vibrating De-oiling Machine

Vibrating De-oiling Machine

-

Continuous Paper Oil Filter

Continuous Paper Oil Filter

-

Double Action Extrusion Press for Φ100mm-Φ50mm Aluminum Seamless Tube

Double Action Extrusion Press for Φ100mm-Φ50mm Aluminum Seamless Tube

-

Continuous Belt Oil Filter

Continuous Belt Oil Filter

-

Bubble Vegetable Washing Machine

Bubble Vegetable Washing Machine

-

IQF Fluidized Tunnel Freezer

IQF Fluidized Tunnel Freezer