Double Action Extrusion Press for Φ120mm-Φ65mm Aluminum Seamless Tube

Long Stroke Aluminum Extrusion Equipment, Double Action Extrusion System, Seamless Tube Extrusion System

Double action extrusion system has an individual piercing system which can be used to extrude aluminum seamless tube. Now, there are long stroke extruder and short stroke extruder available.

Advantages of Long Stroke Extrusion Equipment

1. The long stroke aluminum extruder applies unfixed dummy block, which saves a lot of money for users.

2. Diameter of billet < 152mm.

Advantages of Short Stroke Extrusion Equipment

1. Unfixed dummy block can be used to save cost.

2. Applicable for shorter-length billets.

3. Little deformation in extruded products under high pressure

4. Accuracy of guiding rail and shaft center of extrusion guaranteed.

5. Short idle time.

Technical Data of Seamless Tube Extrusion System

| Model | Rated pressure (MPa) | Size of standard aluminum billet (mm) | Max. circumcircle of profile (mm) | Max. width of profile (mm) | Size of die (mm) | Piercing force (t) | Outer diameter of tube (mm) | Central height of machine (mm) | Total power (kW) | |

| Metric ton | Short ton | |||||||||

| XJ-2500 | XJ-2750 | 21 | Φ229×920 | Φ230 | 310 | Φ500×500 | 600 | Φ120~Φ65 | 1650 | 550 |

Disadvantages of Long Stroke Extrusion Machine

1. Aluminum products processed are more likely to deform under large pressure.

2. While producing, it is hard to guarantee the accuracy of guiding rail and the shaft center of extrusion.

3. Long idle time.

Disadvantages of Short Stroke Extrusion Machine

Unsuitable to extrude aluminum billets with a diameter of 152mm.

Links:https://www.globefindpro.com/products/53872.html

-

Seasoning Tumbler

Seasoning Tumbler

-

Oil Holding Tank

Oil Holding Tank

-

Snack Extruder

Snack Extruder

-

French Fry Cutter

French Fry Cutter

-

VFFS Packaging System

VFFS Packaging System

-

Double Action Extrusion Press for Φ60mm-Φ30mm Aluminum Seamless Tube

Double Action Extrusion Press for Φ60mm-Φ30mm Aluminum Seamless Tube

-

Continuous Fryer

Continuous Fryer

-

Double Action Extrusion Press for Φ90mm-Φ45mm Aluminum Seamless Tube

Double Action Extrusion Press for Φ90mm-Φ45mm Aluminum Seamless Tube

-

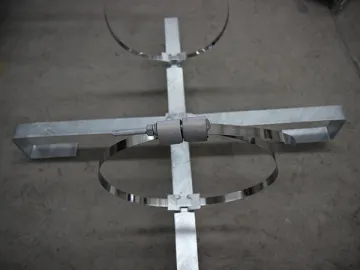

Cross for Storing ADSS Cable

Cross for Storing ADSS Cable

-

Preduster

Preduster

-

Multihead Weigher

Multihead Weigher

-

Vibrating De-oiling Machine

Vibrating De-oiling Machine