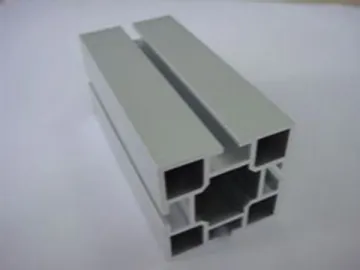

Extrusion Press (for Φ155mm Profile / Flat Bar)

Long Stroke Aluminum Extruder, Short Stroke Extrusion Press, Aluminum Extrusion Machine

As for extrusion equipment for Φ155mm aluminum profile and flat bar, we are able to manufacture two kinds of extruder: long stroke back loaded aluminum extrusion press and short stroke front loaded aluminum extrusion press.

A. Long Stroke Back Loaded Aluminum Extrusion Press

1. The long stroke aluminum extruder applies unfixed dummy block, which saves a lot of money for users.

2. Diameter of billet < 152mm.

B. Short Stroke Front Loaded Aluminum Extrusion Press

1. Aluminum billets of shorter length can be processed with this short stroke extrusion press.

2. There is little deformation in the whole structure while working under huge pressure.

3. It's much easier to ensure the accuracy of guiding rail and the shaft center of extrusion.

4. Short idle time

Technical Parameters

| Model (Al) | Rated pressure (MPa) | Size of standard aluminum billet (mm) | Max. circumcircle of profile (mm) | Max. width of profile (mm) | Size of die (mm) | Central height of machine (mm) | Total power (kW) | |

| Metric ton | Short ton | |||||||

| XJ-1250 | XJ-1400 | 21 | Φ152×620 | Φ155 | 200 | Φ300×300 | 1185 | 230 |

| XJ-1350 | XJ-1500 | 21 | Φ152×620 | Φ155 | 200 | Φ300×300 | 1185 | 230 |

Applications

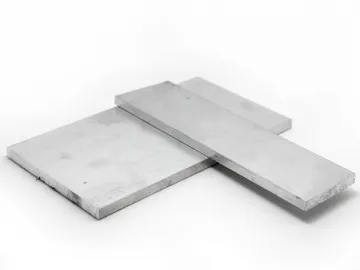

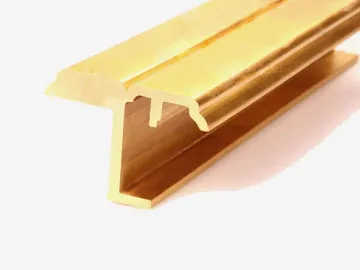

Appropriate for professional production of aluminum profiles, tubes, rods, flat bars, to name a few.

Disadvantages

A. Long Stroke Extrusion Equipment

1. Deformation of the whole structure might occur when working under huge pressure.

2. The accuracy of guiding rail and the shaft center of extrusion are not easy to keep while manufacturing.

3. Long idle time.

B. Short Stroke Extrusion Equipment

1. Expensive fixed dummy block.

2. Unsuitable to extrude aluminum billets with a diameter of 152mm.

Links:https://www.globefindpro.com/products/53912.html

-

Extrusion Press (for Φ95mm Rod)

Extrusion Press (for Φ95mm Rod)

-

Extrusion Press (for Φ170mm Rod)

Extrusion Press (for Φ170mm Rod)

-

Extrusion Press (for Φ130mm Profile / Flat Bar)

Extrusion Press (for Φ130mm Profile / Flat Bar)

-

Extrusion Press (for Φ205mm Profile / Flat Bar)

Extrusion Press (for Φ205mm Profile / Flat Bar)

-

Extrusion Press (for Φ230mm Profile / Flat Bar)

Extrusion Press (for Φ230mm Profile / Flat Bar)

-

Extrusion Press (for Φ330mm Profile / Flat Bar)

Extrusion Press (for Φ330mm Profile / Flat Bar)

-

Extrusion Press (for Φ105mm Rod)

Extrusion Press (for Φ105mm Rod)

-

Extrusion Press (for Φ280mm Profile / Flat Bar)

Extrusion Press (for Φ280mm Profile / Flat Bar)

-

Extrusion Press (for Φ310mm Profile / Flat Bar)

Extrusion Press (for Φ310mm Profile / Flat Bar)

-

Extrusion Press (for Φ260mm Profile / Flat Bar)

Extrusion Press (for Φ260mm Profile / Flat Bar)

-

Extrusion Press (for Φ130mm Profile / Flat Bar)

Extrusion Press (for Φ130mm Profile / Flat Bar)

-

Extrusion Press (for Φ360mm Profile / Flat Bar)

Extrusion Press (for Φ360mm Profile / Flat Bar)