FZQT6-15 Block Making Machine

Brick Making Machine, Wall Block Making Machine, Tile Making Machine, Hollow Brick Making Machine, Paver Making Machine

FZQT6-15 series of block machine is composed of host part, hydraulic station, electrical control cabinet, brick discharging part, plate feeding part, and secondary material feeding system.

Features of FZQT6-15 block machine

1. It is able to produce high-strength public construction block products with the height ranging from 50mm to 300mm.

2. Large exciting force

3. Large working station and lateral cleaning system is employed

4. The specially-designed vibration system and material arranging system make the brick making machine especially suitable for dealing with construction waste and industrial waste

Distinctive advantages

1. Host part

The whole structure employs an integrated design, with all of the joints between different structures being connected using screws to realize a perfect combination with the host part. The modular design helps to simplify the installation process.

2. Vibration system

Being the core part of the block machinery, the vibration system adopts a variable frequency vibration system which acts directly upon the platform. An adjustable high-power vibrator helps to make the machine more compatible with different materials and different brick arrangement. For arranging the raw materials, different frequency is used for vibrating and compressing to realize the max compactness of the blocks. In this way, an optimal forming result accompanied with little cement consumption will be realized in a very short time.

3. Material arranging system

With a rotary arranging method, the forming cycle for standard bricks is shortened to 12s. Rotary arrangement system is particularly suitable for materials with large viscosity like fly ash, or construction waste. In the hopper we set a level gauge to ensure the bricks’ compactness.

4. Control system

This block machine is equipped with self-diagnosis and interlock functions to ensure the safety during production. Human-machine interface makes the operation rather convenient.

5. Details of the brick making machinery

Equipped with secondary material arranging device, it is capable of producing colored bricks for municipal uses. The plate feeding device is fixed behind the block machine. Both plate testing machine and pump oil control device are introduced to make the plate feeding process conduced accurately.

Technical parameters of FZQT 6-15 block making equipment

1. Dimension: 5000*2400*3200 mm

2. Weight: 25t

3. Total power: 43.6kw (2 sets of 7.5kw vibration motors; 4kw motor for arranging materials; 1.5kw motor for discharging blocks; 1.1kw motor for feeding panel; 22kw motor for hydraulic station

4. Vibration method: table mold resonance

5. Pallet dimension: 1200*640*35 mm

6. Vibration frequency: 4500-5400 /min

7. Forming cycle: 18-20 s

8. Max exciting force: 120kN

Production capacity (8 hours/day)

| Block type | Dimension (L* W* H) | Bricks for each plate | Daily output |

| Hollow block | 390*190*190 mm | 6 | 8640 blocks /120m3 |

| Solid block | 240*115*53 mm | 40 | 76000 blocks /112m3 |

| Perforated block | 240*115*90 mm | 20 | 38000 blocks /94m3 |

| Paver | 200*100*60 mm | 30 | 43200 blocks /864m3 |

Links:https://www.globefindpro.com/products/53941.html

-

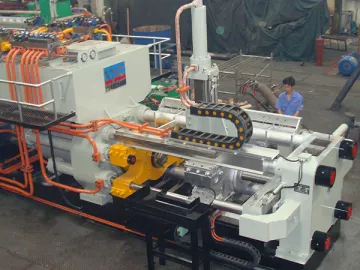

Extrusion Press (for Φ95mm Rod)

Extrusion Press (for Φ95mm Rod)

-

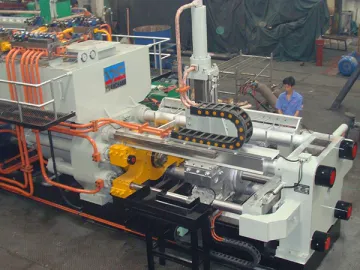

Extrusion Press (for Φ145mm Rod)

Extrusion Press (for Φ145mm Rod)

-

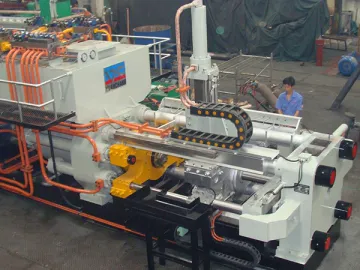

Extrusion Press (for Φ170mm Rod)

Extrusion Press (for Φ170mm Rod)

-

FZQT6-18 Block Making Machine

FZQT6-18 Block Making Machine

-

Double Action Extrusion Press for Φ180mm-Φ80mm Aluminum Seamless Tube

Double Action Extrusion Press for Φ180mm-Φ80mm Aluminum Seamless Tube

-

Extrusion Press (for Φ65mm Rod)

Extrusion Press (for Φ65mm Rod)

-

Double Action Extrusion Press for Φ180mm-Φ80mm Copper Seamless Tube

Double Action Extrusion Press for Φ180mm-Φ80mm Copper Seamless Tube

-

Extrusion Press (for Φ220mm Rod)

Extrusion Press (for Φ220mm Rod)

-

FZQT10-20 Block Making Machine

FZQT10-20 Block Making Machine

-

Double Action Extrusion Press for Φ200mm-Φ80mm Aluminum Seamless Tube

Double Action Extrusion Press for Φ200mm-Φ80mm Aluminum Seamless Tube

-

Window Frame Sanding Machine

Window Frame Sanding Machine

-

Tea Color Sorter

Tea Color Sorter