FZQT6-18 Block Making Machine

Block Machine, Concrete Block Making Machine, Paving Block Making Machine, Solid Brick Making Machine, Perforated Brick Making Machine, Tile Making Machine

The brick making machine is mainly comprised of 5 parts: the host part, the hydraulic station, the electrical control cabinet, the brick discharging part, and the plate feeding part.

Features of the block machine

1. Stable running

FZQT6-18 series block machine adopts advanced electronic control technology, stable hydraulic system and reliable forming technique to ensure the compactness and strength of the bricks.

2. Specially-designed storage device

We have specially designed a storage device to avoid the concrete from getting liquefied in advance and to ensure the uniformity of the blocks.

3. Force feeding device

A force feeding device is set to ensure the compactness of the bricks, making the block making machinery especially suitable for fly ash bricks and concrete perforated bricks.

4. Distinctive vibration method

The table mold resonance vibration mechanism helps the concrete to be fully liquefied in 2-3 seconds, effectively guaranteeing the compactness and strength of the blocks.

5. Wide raw materials

Many kinds of materials like fly ash, cement, sand, stone dust, coal ash, coal gangue, ceramsite sand, furnace slag, steel slag, volcanic slag, as well as other industrial waste and construction waste can be used for making blocks. Different kinds of brick products will be made by using different techniques.

6. Multi-purpose

It can be utilized to make tandard blocks, perforated brick, load-bearing brick, non load-bearing brick, insulation bricks, interlock brick, grass planting brick, paving tile, and curbs. Other decorative bricks like double layer concrete paving blocks and color road bricks can also be produced by additionally using a secondary material arranging device.

7. High production capacity

FZQT6-18 series block machine features a rated production capacity of 50 thousand -120 thousand m3 (standard bricks).

Technical parameters of the block machine

1. Dimension: 3400*2200*2900 mm

2. Weight: 13.5t

3. Total power: 37.85kw (2 sets of 5.5kw vibration motors; 3kw motor for arranging materials; 0.75kw motor for discharging blocks; 1.1kw motor for feeding panel; 22kw motor for hydraulic station)

4. Vibration method: table mold resonance

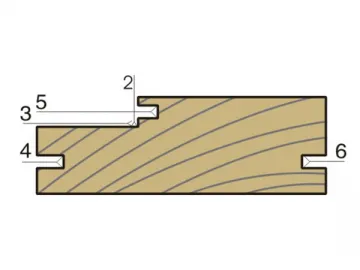

5. Pallet dimension: 870*685*18/40 mm

6. Vibration frequency: 4500 /min

7. Forming cycle: 13-18 s

8. Max exciting force: 120 kN

Production capacity (8 hours/day)

| Brick type | Dimension (L* W* H) | Bricks for each plate | Daily output |

| Hollow block | 390*190*190mm | 8 | 11520 blocks/160m3 |

| Solid brick | 240*115*53mm | 36 | 70000 blocks/102m3 |

| Perforated brick | 240*115*90mm | 18 | 35000 blocks/87m3 |

| Paver | 200*100*60mm | 21 | 30000 blocks/600m2 |

Links:https://www.globefindpro.com/products/53945.html

-

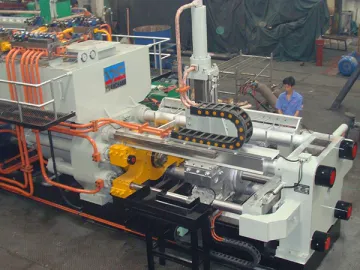

Double Action Extrusion Press for Φ180mm-Φ80mm Aluminum Seamless Tube

Double Action Extrusion Press for Φ180mm-Φ80mm Aluminum Seamless Tube

-

Extrusion Press (for Φ65mm Rod)

Extrusion Press (for Φ65mm Rod)

-

Extrusion Press (for Φ195mm Rod)

Extrusion Press (for Φ195mm Rod)

-

Extrusion Press (for Φ80mm Rod)

Extrusion Press (for Φ80mm Rod)

-

Slitting and Cut-To-Length Line for 0.3-2mm Thickness

Slitting and Cut-To-Length Line for 0.3-2mm Thickness

-

Doorframe Milling Machine

Doorframe Milling Machine

-

Extrusion Press (for Φ170mm Rod)

Extrusion Press (for Φ170mm Rod)

-

Extrusion Press (for Φ145mm Rod)

Extrusion Press (for Φ145mm Rod)

-

Extrusion Press (for Φ95mm Rod)

Extrusion Press (for Φ95mm Rod)

-

FZQT6-15 Block Making Machine

FZQT6-15 Block Making Machine

-

Double Action Extrusion Press for Φ180mm-Φ80mm Copper Seamless Tube

Double Action Extrusion Press for Φ180mm-Φ80mm Copper Seamless Tube

-

Extrusion Press (for Φ220mm Rod)

Extrusion Press (for Φ220mm Rod)