Flat Bar Straightening and Cutting Machine

Flat Bar Processing Machinery, Flat Bar Straightening and Cutting Equipment, Metal Bar Straightening and Cutting Machine

As being a complete line, the flat bar processing machinery is most often applied for cutting flat bars into strips. Main processing steps include uncoiling, deburring, chamfering, longitudinal and transverse straightening and cutting. In consideration of special requirements of different products, this machine is able to make flat bars with round and square edges.

Characteristics of Metal Bar Straightening and Cutting Machine

1. Compact structure with high performance

2. Low output but high added value

3. Easy to operate and adjust

Applications

Wide applications have been found in serrated bar, building construction, auto and steel industries.

Parameters of Flat Bar Straightening and Cutting Equipment

| Application | hot rolled steel, galvanized, etc. |

| Thickness of coil plate | 1-6mm |

| Width of coil plate | 20-100mm |

| Inaccuracy of width | -0.9- 0.3mm |

| Inaccuracy of fixed length | 0- 5mm |

| Bending distance | ≤2.5mm/m |

| Cutting spacing | ≤2mm |

| Line speed | 25m/min |

| Production | Consistent |

| Operators | 1 technician and 1 worker |

| Power | 380V three-phase 50Hz |

| Size | 12m(L)×4m(W) |

| Color | Green or customized |

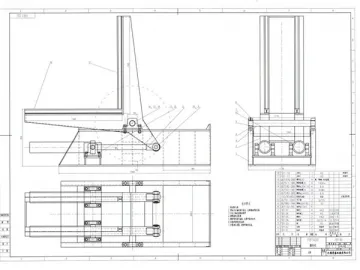

Design Drawing

Major Configurations of Straightening and Cutting Line

1. Decoiler; 2. 7-roller straightener; 3. Deburring and extruding machine; 4. 2-roller pinching and pressing device; 5. Longitudinal straightener; 6. Surface straightener; 7. Hydraulic cutting machine; 8. Stacker table; 9. Hydraulic system; 10. Electrical control system

Decoiler

7-roller straightener

Deburring and extruding machine

2-roller pinching and pressing device

Longitudinal straightener

Surface straightener

Hydraulic cutting machine

Standard Models

| Model | Thickness(mm) | Width(mm) |

| BG-6X80 | 2-6 | 20-80 |

| BG-12X200 | 6-12 | 25-200 |

If you decide the machine that you want, please tell us the model number. We will send first quotation accordingly------confirm design with you------send drawings of your machine------confirm order------prepare production drawings and arrange production--------assemble--------test and inspect-------deliver--------install.

We will keep you informed of each manufacture procedure.

Some Customers

In 2012, a South African customer purchased a standard 6x80 flat bar straightening and cutting machine and a Philippine customer bought a 12x200 flat bar processing machine together with the slitting line.

In 2013, our Indian customer purchased a 4x100 stainless steel flat bar machine with recoiler.

In 2014, a client from Indonesia bought two 6x80 flat bar straightening and cutting machines and also bought 4x1600 cut to length line together. Another Indonesia customer bought four 6x80 flat bar processing machines.

In 2015, a Thailand customer bought two 6x80, one 8x130 and one 12x200 flat bar straightening and cutting machines.

In 2016, the machine has found a market share in Mexico, Venezuela, Kenya, Saudi Arabia and so forth.

Questions You May Ask

1. How is the package?

Processing machines will be bare, all rolling components will undergo anti-rust treatment.

2. How long to deliver?

For standard lines, it takes 30-60 days. For un-standard lines, 60-70 days.

3. How many Containers are needed for the whole line?

1x20GP

4. How many workers required to operate this line?

Three workers are required

5. How about the installation?

As the entire machine line is simply easy to install, our company will remotely instruct customers to install by themselves. If needed, we can also dispatch an engineer to offer on-site installation service. It will take about 5-7 days.

6. What brand you used for the machine?

Usually, we select Chinese famous brands for the electrical, hydraulic and pneumatic parts. But if you have special requirements, we also provide custom service upon request.

Links:https://www.globefindpro.com/products/53980.html

-

Door Leaf/Slab Edge Sanding Machine

Door Leaf/Slab Edge Sanding Machine

-

Economical Slitting Line

Economical Slitting Line

-

Thick Steel Sheet Cut-To-Length Line

Thick Steel Sheet Cut-To-Length Line

-

Edge Sander

Edge Sander

-

Chest Press AXD-705

Chest Press AXD-705

-

Seated Leg Curl AXD-5002

Seated Leg Curl AXD-5002

-

Upender / Coil Tilter

Upender / Coil Tilter

-

Multi-Screen Encoder / Transcoder

Multi-Screen Encoder / Transcoder

-

Thick Steel Sheet Slitting Line

Thick Steel Sheet Slitting Line

-

Molding Sanding Machine

Molding Sanding Machine

-

Slitting and Cut-To-Length Line

Slitting and Cut-To-Length Line

-

Cold Rolled Steel Slitting Line

Cold Rolled Steel Slitting Line