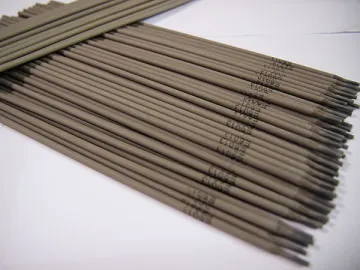

AWS E7018

Introduction:

The E7018 is a type of carbon steel electrode with an iron powder low-hydrogen potassium coating. The welding wire features a significant deposition efficiency due to the iron powder in its coating. The stable arc, few spatter, slag detachability and excellent welding performance, make this type of welding rod an outstanding choice for many welding operations.

Applications:

Often used for welding carbon steel and low-alloy steel structures, such as 16Mn, etc.

Chemical Composition of Deposited Metal (%):

| Chemical Composition | C | Mn | Si | S | P | Ni | Mo | Cr | V |

| Guarantee Value | ≤0.12 | ≤1.60 | ≤0.75 | ≤0.035 | ≤0.040 | ≤0.30 | ≤0.30 | ≤0.20 | ≤0.08 |

Diffusible Hydrogen Content in Deposited Metal:

≤8.0ml/100g (glycerine hydrogen test)

Mechanical Properties of Deposited Metal:

| Test Item | R m (MPa) | R eL (Mpa) | A(%) | KV 2 (J) |

| Guarantee Value | ≥490 | ≥400 | ≥22 | ≥27(-30℃) |

| General Result | 520~580 | ≥410 | 24~30 | 80~200 |

Reference Current (DC )L:

| Electrode Diameter(mm) | φ2.5 | φ3.2 | φ4.0 | φ5.0 |

| Welding Current (A) | 60~100 | 80~140 | 110~210 | 160~230 |

X-ray Radiographic Inspection:

ⅠDegree

Packing Details:

In carton of 20kgs/net, consisting of 8 boxes x 2.5kgs for 2.5mm, & 4 boxes x 5kgs for other sizes.

With/ without pallets (fumigation-free pallets) upon customer’s request.

Instructions:

1. The electrodes must be baked under 300~350℃ for an hour before welding and applied as soon as baking is completed.

2. The stains on the electrode, such as rust, oil stains, moisture, etc., must be cleared away before welding.

3. When welding, a short arc must be used and a stringer bead is suitable.

Links:https://www.globefindpro.com/products/54313.html