AWS E7024

Introduction:

The E7024 carbon steel electrode is an iron powder titania coated welding consumable with an amazing deposition efficiency of 150%. The AC/DC suitable welding wire is used for angle/fillet welding in downhand position, downhand welding and flat fillet welding. These electrodes have a stable arc, produce fewer spatter and provide a neat welding appearance.

Applications:

Applicable for welding carbon steel and low-alloy structures, such as A, B and D steel, ships, locomotive vehicles, boilers of 16Mn type, etc.

Chemical Composition of Deposited Metal (%):

| Chemical Composition | C | Mn | Si | S | P |

| Guarantee Value | ≤0.12 | ≤1.25 | ≤0.9 | ≤0.035 | ≤0.040 |

Mechanical Properties ofDeposited Metal:

| Test Item | R m (MPa) | R eL (Mpa) | A (%) | KV 2 (J) |

| Guarantee Value | ≥490 | ≥400 | ≥17 | ≥27(0 ℃ ) |

| General Result | 500~580 | 410~480 | 17~28 | 50~100 |

Reference Current (AC, DC):

| Electrode Diameter(mm) | φ4.0 | φ4.5 | φ5.0 | φ5.5 | φ6.0 |

| Welding Current (A) | 140~200 | 150~210 | 160~220 | 180~240 | 210~280 |

X-ray Radiographic Inspection:

Degree

Packing Details:

In cartons of 20kgs/net, consisting of 8 boxes x 2.5kgs for 2.5mm, & 4 boxes x 5kgs for other sizes.

With/ without pallets (fumigation-free pallets) upon customer’s request.

Instructions:

1. Any stains on the welding surface, such as rust, oil stains, moisture, etc., must be cleared away before welding.

2. The electrodes must be baked under 180~200℃ for an hour before welding due to long term storage effects.

Links:https://www.globefindpro.com/products/54323.html

-

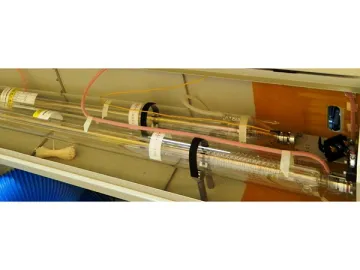

CM Series CO2 Laser Cutting and Engraving Machine

CM Series CO2 Laser Cutting and Engraving Machine

-

G-1325 CO2 Laser Cutting and Engraving Machine

G-1325 CO2 Laser Cutting and Engraving Machine

-

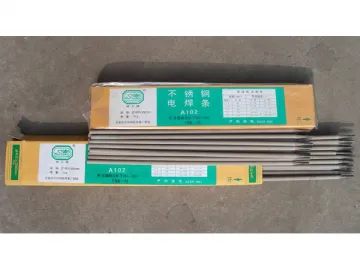

AWS E308-16

AWS E308-16

-

CV-2000Y (LCD Display)

CV-2000Y (LCD Display)

-

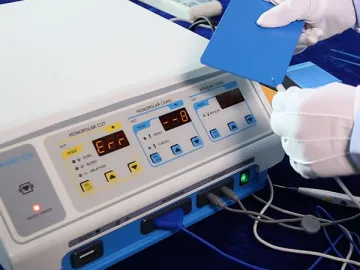

Radiofrequency Electrosurgical Unit

Radiofrequency Electrosurgical Unit

-

Plasma Cut Electrosurgical Unit

Plasma Cut Electrosurgical Unit

-

AWS E6010

AWS E6010

-

CV-2000A (LCD Display)

CV-2000A (LCD Display)

-

X-6060 Fiber Laser Cutting Workstation

X-6060 Fiber Laser Cutting Workstation

-

CV-2000I (Digital Display)

CV-2000I (Digital Display)

-

E-4030 CO2 Laser Cutting and Engraving Machine

E-4030 CO2 Laser Cutting and Engraving Machine

-

CV-2000AI (Digital Display)

CV-2000AI (Digital Display)