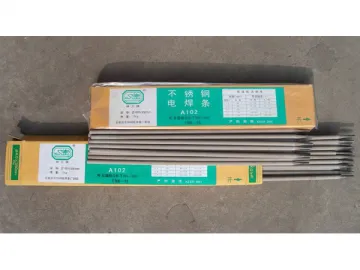

AWS E308-16

Introduction:

Our AWS E308-16 stainless steel electrodes are lime-titania coated for excellent mechanical strength and corrosion resistance. The AC/DC welding wires are highly reliable and will last for many years after application.

Applications:

Used for welding corrosion-resistant 0Cr19Ni9 and 0Cr19Ni11Ti stainless steel structures below 300℃

Chemical Composition of Deposited Metal (%):

| Chemical Composition | C | Mn | Si | S | P | Cu | Ni | Mo | Cr |

| Guarantee Value | ≤0.08 | 0.5~2.5 | ≤0.90 | ≤0.030 | ≤0.040 | ≤0.75 | 9.0~11.0 | ≤0.75 | 18.0~21.0 |

Mechanical Properties ofDeposited Metal:

| Test Item | R m (MPa) | A(%) |

| Guarantee Value | ≥550 | ≥ 3 5 |

Reference Current (DC ):

| Electrode Diameter(mm) | φ2.0 | φ2.5 | φ3.2 | φ4.0 | φ5.0 |

| Welding Current (A) | 40~80 | 50~100 | 70~130 | 100~160 | 140~200 |

Packing Details:

In cartons of 20kgs/net, consisting of 8 boxes x 2.5kgs for 2.5mm, & 4 boxes x 5kgs for other sizes.

With/ without pallets (fumigation-free pallets) upon customer’s request.

Instructions:

1. The electrodes should be baked under 200-250℃ for an hour before welding.

2. D/C is preferred and the current should not be too strong.

Links:https://www.globefindpro.com/products/54326.html

-

CV-2000Y (LCD Display)

CV-2000Y (LCD Display)

-

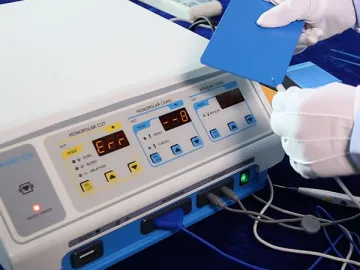

Radiofrequency Electrosurgical Unit

Radiofrequency Electrosurgical Unit

-

Plasma Cut Electrosurgical Unit

Plasma Cut Electrosurgical Unit

-

F-20 Fiber Laser Galvo Marking Machine

F-20 Fiber Laser Galvo Marking Machine

-

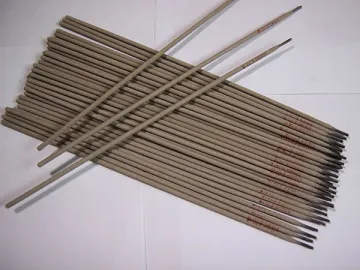

Hardfacing Welding Electrodes

Hardfacing Welding Electrodes

-

LF-1530 Fiber Laser Cutting Machine

LF-1530 Fiber Laser Cutting Machine

-

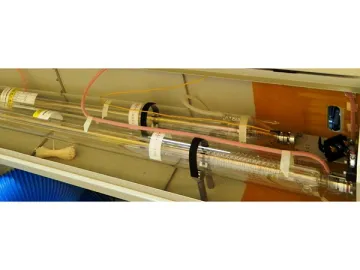

G-1325 CO2 Laser Cutting and Engraving Machine

G-1325 CO2 Laser Cutting and Engraving Machine

-

CM Series CO2 Laser Cutting and Engraving Machine

CM Series CO2 Laser Cutting and Engraving Machine

-

AWS E7024

AWS E7024

-

AWS E6010

AWS E6010

-

CV-2000A (LCD Display)

CV-2000A (LCD Display)

-

X-6060 Fiber Laser Cutting Workstation

X-6060 Fiber Laser Cutting Workstation