AWS ENiFe-C1

Introduction:

The ENiFe-C1 is a cast iron electrode with a Ni-Fe alloy core wire and graphite coating. These welding electrodes provide high strength, good plasticity welds that are crack resistant. These electrodes are suitable for cast iron components with high phosphorus content as well. They are often used for welding gray cast iron and ball graphite cast iron under normal temperatures or preheated to about 200℃. This welding rod is AC/DC suitable unlike the AWS Eni-C1 electrodes.

Applications:

Suitable for the repair and welding of gray cast iron with high intensity and ball graphite cast iron, such as cylinders, engine bearers, gearwheels, rollers, etc.

Chemical Composition of Deposited Metal (%):

| Chemical Composition | C | Mn | Si | S | Ni | Fe | Total Quantity of Other Elements |

| Guarantee Value | ≤2.00 | ≤1.80 | ≤2.50 | ≤0.030 | 45~60 | Balance | ≤1.00 |

Reference Current (AC, DC ):

| Electrode Diameter(mm) | φ3.2 | φ4.0 | φ5.0 |

| Welding Current (A) | 50~100 | 70~120 | 110~180 |

Packing Details:

In carton of 20kgs/net, consisting of 8 boxes x 2.5kgs for 2.5mm, & 4 boxes x 5kgs for other sizes.

With/ without pallets (fumigation-free pallets) upon customer’s request.

Instructions:

1. The electrodes must be baked under about 200℃ for an hour before welding.

2. Hammering the weld gently can reduce stress on the weld and prevent cracking.

Links:https://www.globefindpro.com/products/54335.html

-

CV-2000Y (Digital Display)

CV-2000Y (Digital Display)

-

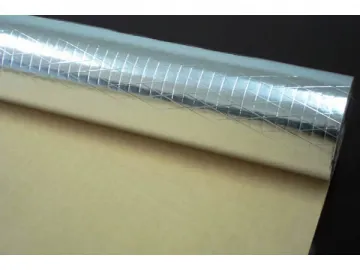

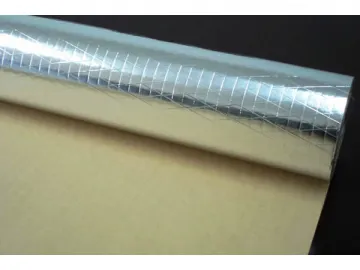

FSK60A Reinforced Foil Facing

FSK60A Reinforced Foil Facing

-

FSK60D Reinforced Aluminum Insulation Facing

FSK60D Reinforced Aluminum Insulation Facing

-

PSKF50A PP Scrim Kraft Facing

PSKF50A PP Scrim Kraft Facing

-

FPEF150 Double Sided Aluminum Woven Cloth

FPEF150 Double Sided Aluminum Woven Cloth

-

Aluminum Foil Facing

Aluminum Foil Facing

-

CV-2000A (Digital Display)

CV-2000A (Digital Display)

-

AWS E309-16

AWS E309-16

-

LF-1530 Fiber Laser Cutting Machine

LF-1530 Fiber Laser Cutting Machine

-

Hardfacing Welding Electrodes

Hardfacing Welding Electrodes

-

F-20 Fiber Laser Galvo Marking Machine

F-20 Fiber Laser Galvo Marking Machine

-

Plasma Cut Electrosurgical Unit

Plasma Cut Electrosurgical Unit