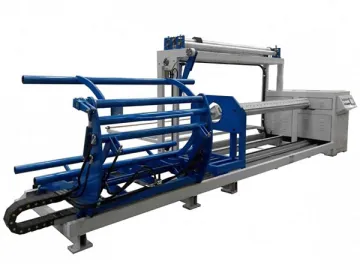

Storage Shelves Welding Machine

Storage Shelf Welder / Shelving Welder / Shelf Machine

Features of the Storage Shelves Welding Machine

1. Line wires are fed from pre-cut wires and the steel rod is welded on top of the strip sheet.

2. Both the welding electrodes and transformers are equipped with a water-cooling system to prolong the service life of the shelf machine.

3. The welding machine adopts synchronous power control and separate-control for singular operation or tandem welding.

4. The main structure of the shelving welder adopts a motor drive, spring weighted, minimizing operating costs.

5. Welding material can be hot-rolled ribbed bar, cold-rolled ribbed bar, hot-rolled plain bar, cold-rolled plain bar, etc.

Technological processes of the Storage Shelves Welding Machine Technical Parameters of Storage Shelves Welding Machine

| Model | 1200 |

| Quantity of welding spots | 24 |

| Width of mesh | 1200 mm |

| Wire diameter | 3-6 mm |

| Longitudinal wire spacing | 50 mm |

| Transverse wire spacing | ≥25 mm |

| Power | 250 KVA |

| Welding speed | 30-40t/min |

| Control system | PLC |

Applications

This machine can be used in the production of wire mesh storage shelves.

Links:https://www.globefindpro.com/products/54454.html

-

Automatic Wire Straightening and Cutting Machine

Automatic Wire Straightening and Cutting Machine

-

Multi-Function Fluid-Bed Granulator / Coater

Multi-Function Fluid-Bed Granulator / Coater

-

Vibrating Fluid Bed Dryer

Vibrating Fluid Bed Dryer

-

Twin-Shaft Paddle Mixer / Zero-Gravity Mixer

Twin-Shaft Paddle Mixer / Zero-Gravity Mixer

-

Ultra-Fine Grinding Mill

Ultra-Fine Grinding Mill

-

Wire Mesh Rolling Machine

Wire Mesh Rolling Machine

-

Fluidized Bed Granulator

Fluidized Bed Granulator

-

Drum Dryer (with Scraper)

Drum Dryer (with Scraper)

-

Vacuum Harrow Dryer

Vacuum Harrow Dryer

-

Pressure Nozzle Spray Dryer

Pressure Nozzle Spray Dryer

-

Fluidized Bed Jet Mill

Fluidized Bed Jet Mill

-

Centrifugal Granulation Spray Dryer

Centrifugal Granulation Spray Dryer