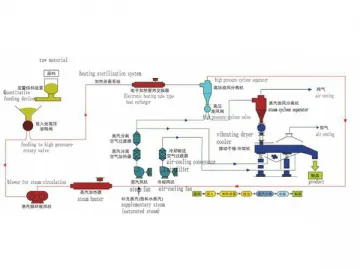

Triple Effect Forced Circulation Evaporator

Application Scope:

This design can be suitable to concentrate such materials` solutions as Chinese traditional medicines, Western medicines, dextrose, amylum, chemical, MSG, milk products and so on, especially to concentrate the thermal sensitive materials under the low temperature vacuum condition. The different types of concentrators listed in the follow table are available for the clients to choose according to their different requirements to the capacity of the concentrator.

Features and Advantages:

1. This design adopts the technology of outer heating with natural circulation and vacuum negative pressure evaporating to speed up the evaporating process and increase the concentration ratio. The concentration ratio can reach 1.2~1.3.

2. This machine adopts the technology of triple-effect evaporating at same time. Therefore, the second steam can be utilized repeatedly. As a result, the investment in the boiler and the energy consumption is reduced in a large scale. Compared with the single effect concentrator, the energy consumption can be reduced by 70%. We can promise that within a year the benefit customers get from the saved energy is enough to redeem the whole investment in the machine.

3. This design has multi-functions, which is one of its most remarkable features. It can be used to reclaim ethanol and the concentration can reach 80%.The single-effect, double-effect and triple-effect can be fed by the row materials alternatively and continuously.

4. All the places directly contacting with the liquid materials are made of SUS304 stainless steel. It also has a good-looking appearance. It’s heater, evaporator have impressed thermal insulation and the thermal insulation are wrapped by stainless steel sheet to meet the standard of GMP.

For technical parameters, please refer to attachment.

Links:https://www.globefindpro.com/products/54470.html

-

Full Bore Floating Ball Valve DN200-DN350

Full Bore Floating Ball Valve DN200-DN350

-

Floating Ball Valve DN65-DN150

Floating Ball Valve DN65-DN150

-

Spray Dryer (for Chinese Traditional Medicine Extract)

Spray Dryer (for Chinese Traditional Medicine Extract)

-

Spherical Dryer

Spherical Dryer

-

Filter Ball Valve DN65-DN1000

Filter Ball Valve DN65-DN1000

-

Vacuum Belt Continuous Dryer For Liquid

Vacuum Belt Continuous Dryer For Liquid

-

Floating Ball Valve DN15-DN50

Floating Ball Valve DN15-DN50

-

Dynamic Production Line for Extracting Chinese Traditional Medicine

Dynamic Production Line for Extracting Chinese Traditional Medicine

-

Powder / Granule Sterilization Device

Powder / Granule Sterilization Device

-

Pulse Jet Baghouse Dust Collector

Pulse Jet Baghouse Dust Collector

-

Hot Reflux Extracting and Concentrating Unit

Hot Reflux Extracting and Concentrating Unit

-

Horizontal Spray Dryer

Horizontal Spray Dryer