High-Speed Damp Mixing Granulator

Description:

GSL Series high-speed damp mixing granulator is a kind of high efficient equipment, and within one operation it can mix different powder materials and granulate them to particles. It is widely used in pharmaceutical, food, and chemical industry etc.

Features:

The machine adopts horizontal cylinder or cone structure, and the user can freely choose.

This machine adopts horizontal cylinder construction, reasonable structure, and there is no dead corners, no metal stain, no ash deposit; dry mixing--wet mixing--granulation are finished in the same sealed container, as can reduce procedures, meeting the requirements of “GMP” .

Granulation time is short due to its high efficiency and energy-saving.

Drive shaft with air-filling seal, which can be changed to water when washing. Applying fluidized granulation,the particle is similarly spherical, its texture is uniform, and its fluidity is good, as can provide most ideal granule material to tablet pressing procedure.

Compared to traditional process, 25% of cohesive is reduced and the drying time is shortened. The dry mixing time per batch is 2 minutes, and granulation time is 1~4 minutes, therefore compared to traditional process,work efficiency is raised at 4~5 times.

The whole operation has strict safe and protective measures.

When there is very big difference between the principal agent or base and auxiliary agent, it can still achieve uniform mixing, and there is no phenomenon of delamination.

Application:

It is suitable for pharmaceutical industry, foodstuff industry, chemical industry and etc. The granule is made from powder to damp granule in which the adhesive should be injected in.

Work Principle:

The GSL high speed damp mixer granulator is a new generation granulator combining wet mixing and granulation functions. By adopting a lot of state-of-the-art technologies based on the existing granulator, it is a user-friendly equipment。GSL series damp mixer granulator fully embodies a perfect match of facility and technology, coming with rational structure, convenient operation and remarkable functionality.

Powder materials and adhesives are mixed fully into wet soft materials by bottom mixing paddle of cylindrical vessel, then the materials are cut into uniform wet granules by side-mounted high speed smashing paddle inside the mixer granulator.

Technical Parameters:

| Item | Specification | ||||||||

| Name | Unit | 10 | 50 | 150 | 200 | 250 | 300 | 400 | 600 |

| Volume | L | 10 | 50 | 150 | 200 | 250 | 300 | 400 | 600 |

| Output/Batch | kg/batch | 3 | 15 | 50 | 80 | 100 | 130 | 200 | 280 |

| Mixing speed | r.p.m | 300/600 | 200/400 | 180/270 | 180/270 | 180/270 | 140/220 | 106/155 | 80/120 |

| Mixing power | kw | 1.5/2.2 | 4/5.5 | 6.5/8 | 9/11 | 9/11 | 13/16 | 18.5/22 | 22/30 |

| Cutting speed | r.p.m | 1500/ 3000 | 1500/ 3000 | 1500/ 3000 | 1500/ 3000 | 1500/ 3000 | 1500/ 3000 | 1500/ 3000 | 1500/ 3000 |

| Cutting power | kw | 0.85/1.1 | 1.3/1.8 | 2.4/3 | 4.5/5.5 | 4.5/5.5 | 4.5/5.5 | 6.5/8 | 9/11 |

| Compressed air consumption | 3m /min | 0.6 | 0.6 | 0.9 | 0.9 | 0.9 | 1.1 | 1.5 | 1.8 |

| Dead weight | kg | 250 | 500 | 800 | 1000 | 1300 | 1800 | 2200 | 2600 |

| Model | A | B | C × D | E | F |

| 10 | 270 | 750 | 1000×650 | 745 | 1350 |

| 50 | 320 | 950 | 1250×800 | 970 | 1650 |

| 150 | 420 | 1000 | 1350×800 | 1050 | 1750 |

| 200 | 520 | 1100 | 1650×850 | 1450 | 2050 |

| 250 | 550 | 1100 | 1650×850 | 1450 | 2050 |

| 300 | 550 | 1150 | 1700×900 | 1500 | 2200 |

| 400 | 670 | 1150 | 1860×1050 | 1650 | 2350 |

| 600 | 750 | 1250 | 2000×1050 | 1800 | 2400 |

Links:https://www.globefindpro.com/products/54490.html

-

Roller Compactor / Dry Granulator

Roller Compactor / Dry Granulator

-

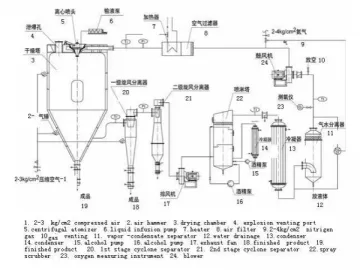

Closed Cycle Spray Dryer

Closed Cycle Spray Dryer

-

Organic Compound Fertilizer Production Line

Organic Compound Fertilizer Production Line

-

Rotary Atomizer

Rotary Atomizer

-

Stevia project

Stevia project

-

Extended Stem Trunnion Ball Valve DN350-DN1400

Extended Stem Trunnion Ball Valve DN350-DN1400

-

Continuous Vacuum Belt Dryer (for Liquid)

Continuous Vacuum Belt Dryer (for Liquid)

-

Continuous Vacuum Belt Dryer (for Solid)

Continuous Vacuum Belt Dryer (for Solid)

-

Full Bore Floating Ball Valve DN15-DN150

Full Bore Floating Ball Valve DN15-DN150

-

Finned Tube Heat Exchanger

Finned Tube Heat Exchanger

-

Vacuum Belt Continuous Dryer For Powder

Vacuum Belt Continuous Dryer For Powder

-

Sterilization Machine

Sterilization Machine