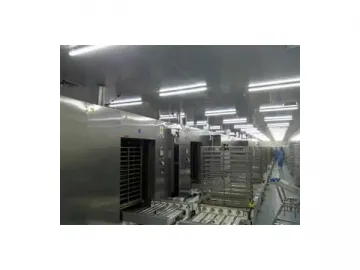

Saturated Steam Sterilizer (for Ampoules / Vials)

Application

1. Ampoule

2. Vial

3. Others

Chamber

The chamber is made of SS 304 or SS 316L, and is designed and manufactured according to GB-150 standards for steel pressure vessels. It is inspected by the National Technical Inspection Department in China, which ensures safety of both the machine and operator.

Finely polished

Smooth

Corrosion-proof

Easy to clean

Loading

1. Ampoule tray loaded in inner trolley

2. Outer carrying trolley

Safety System & Alarm

Safety valves for Chamber

Alarms

1. Exceed pressure

2. Exceed temperature

3. Low temperature

4. Door failure

5. Cycle end

Door Interlock

When the door is not closed, steam cannot enter chamber.

When the chamber steam pressure is more than 0.027MPa, doors cannot open.

Pipeline System

1. Stainless steel pipes without dead angle, ensuring complete drainage

2. High quality pneumatic valve

3. Clamp connection, easy to install and maintain

Automatic Control, Easy Operation

1. PLC and HMI from Mitsubishi/Siemens

2. Automatic and manual operation mode

3. Stable performance and precise control

4. Multiple sterilizing cycles

5. Sterilizing parameters can be set on HMI

6. Print time, temperature, and pressure

Cycle Description

| Item | Cycle/Phase | Setable Parameters |

| GLASS AMPOULE | Vacuum---Heat---Sterilize ---Ampoule leak test---clean ---End | Design Pressure: 0.165Mpa; Design Temperature: 129℃ , Sterilize Time: 0~999sec |

Links:https://www.globefindpro.com/products/55357.html

-

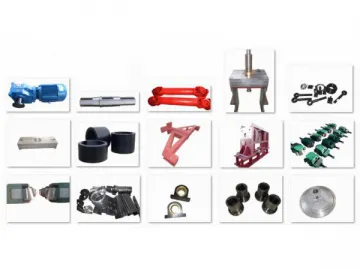

Spare parts

Spare parts

-

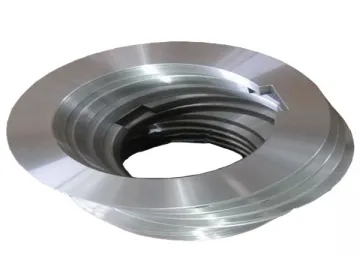

Slitting Knives / Cut-To-Length Knives

Slitting Knives / Cut-To-Length Knives

-

Medical and Hospital Sterilizer

Medical and Hospital Sterilizer

-

Forged Steel Hex Head Bushings

Forged Steel Hex Head Bushings

-

Butt Weld Saddles

Butt Weld Saddles

-

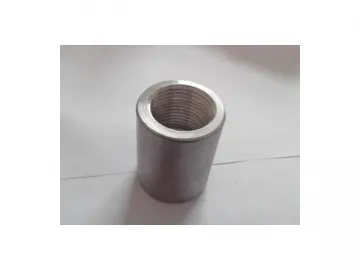

Forged Steel Bosses

Forged Steel Bosses

-

Pulse Vacuum Sterilizer (with SIP Air Filter)

Pulse Vacuum Sterilizer (with SIP Air Filter)

-

Horizontal Cylindrical Pressure Steam Sterilizer

Horizontal Cylindrical Pressure Steam Sterilizer

-

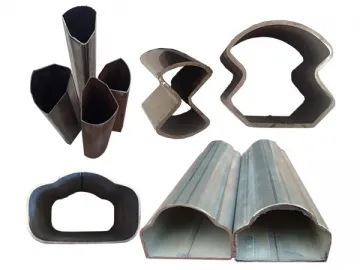

Section Tubes and Pipes

Section Tubes and Pipes

-

Welded Square & Rectangle Tubes and Pipes

Welded Square & Rectangle Tubes and Pipes

-

Dry Heat Sterilizer / Oral Bottle Sterilizer

Dry Heat Sterilizer / Oral Bottle Sterilizer

-

Other Accessories

Other Accessories