Inflatable Air Cushion Making Machine

JTZD-700AK

JTZD-700AK

Samles

Samles

Main Technical Data

JTZD-700AK

Samles

Samles

Main Technical Data

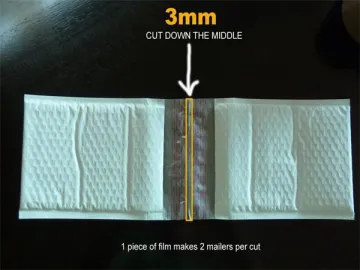

| Machine function | air inflation, 2layers double unwinding, with air inflation tube infeeding |

| Three servo motors with PLC( Panasonic ) Main drive: AC motor with inverter Temp. control: 12 stages | |

| Material type | BOPP, COPP, PET, PVC, nylon, multi-layer extrusion film, Al, plated film, Paper-Plastic laminated web |

| Working pace | 80 p /min (speed depends on film material and bag shape) |

| Unwind line speed | ≤ 35 m/min (speed depends on film material and bag shape) |

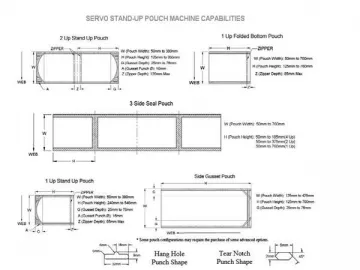

| Bag size | Length:50-500mm, (when overly long, multiple infeeding will adopted)Max. width: 700mm |

| Material max. size | Ф600×1440mm (dia.× width) |

| Web position precision | ≤± 0.5mm |

| Heat sealing knife | Vertical: 4 groups , (top/bottom heating)Cooling:1 groups(top/bottom cooling) Horizontal: 3 groups, Cooling: 1 group (top/bottom cooling) |

| Temp control electric heating block | 12 pcs |

| Temp. setting range | 0~ 300 ℃ |

| Power consumption | 35kw |

| Machine size | 13500 x 1500 x 1700mm (L x W x H) |

| Machine weight | Approx.50 KG |

| Machine color | Deep blue machine body, yellow shell |

| Control system | High speed bag making control system |

Other search items: air cushions / air pillows

Scan QR to Read

Links:https://www.globefindpro.com/products/55452.html

Links:https://www.globefindpro.com/products/55452.html

Recommended Products

Hot Products