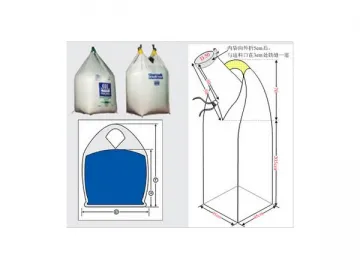

UN Certified Bulk Bag (for Hazardous Goods)

(for Hazardous Goods)

Used for packaging and transporting hazardous goods.

Material: polypropylene or polyethylene

Shape: square big bag

Top: inlet

Bottom: Plain bottom or spout bottom

Lifting loops: top lifting strap, wrapped bottom belt, side lifting loop

Capacity: 500-2300L. Standard models are in stock for each set of specifications.

SWL: 0.5-3t

Safe factors: 5:1, 6:1

Size: Customizable

UN approved bulk bags are most often employed to transport hazardous goods. They are designed to the most stringent test and safety standards, such as ADR/RID/INDG and ICAP-TI requirements. A hazardous waste bag needs to pass a series of rigorous tests to legally contain or transport hazardous materials.

1. Top lift test

2. Tear test

3. Stacking test

4. Collapse test

5. Righting test

U.N. Mark

Bulk bags passing these test will bear UN marks. For bags containing and transporting hazardous materials, the letter N needs to be stamped on them in addition to the detailed model no. such as 13H3/Y/10.03/A/PA-03/12345-Storsack/5400/1000. Note that this long string of numbers and letters contain key information for reference, including design model no., manufacturer, stacking height, and maximum safe working load, etc.

Links:https://www.globefindpro.com/products/55458.html