Plate and Frame Filter Press

Filter press is a dehydration device, which makes use of a slurry pump to squeeze the water from filter cloth. The product features stable performance, high degree of automation, programmable control, safety, high reliability and easy operation. It is able to accomplish backwashing as well.

It is made up with filter plate, filter frame, filter cloth and pressing membrane. Generally, both sides of the filter plate are covered with filter cloth. The filter plate will consist of a membrane plate and a lateral plate if the pressing membrane is required. The filter plate is produced through precision casting of plastic steel, so that it is durable and able to withstand high temperature and high pressure.

The filter press falls into two categories including chamber type and plate and frame type. The former is usually applied for filtration of concentrate. It also suitable for filtration of tailings which will be discharged in dry environment later. The size of finished product can reach 500 meshes. The latter is suitable for hydration of ore fines such as gold ore, sliver ore, copper ore, iron ore, zinc ore and rare earth. It is also can be applied for treatment of tailings.

Chamber type and plate type are respectively shown in the left and right figures.

1. fixed end plate

2. filter frame

3. filter plate

4. compressing plate

5. compressing hand wheel

6. slide rail

1. thrust plate

2. cephalic plate

3. filter plate

4. filter cloth

5. tail board

6. compressing plate

7. beam

8. hydraulic cylinder

9. foundation of hydraulic pressure station

10. hydraulic pressure station

Technical Parameters

| Model | Filtration Area (m2) | Filtration Chamber Number | Filter Plate Size | Thickness of Filtered Material (mm) | Filtration Chamber Volume(m3) | Filtration Pressure (Mpa) | Foundation Center (mm) | Dimension ( L ×W × H) (mm) | Motor Power (kw) | Weight (kg) |

| XM/AZ800U | 20 | 20 | 800×800×55 | 25 | 0.239 | 0.5 | 2265 | 3215×1320×1160 | 2.2 | 2073 |

| XM/AZ800U | 30 | 30 | 800×800×55 | 25 | 0.365 | 0.5-0.8 | 2815 | 3765×1320×1160 | 2.2 | 3090 |

| XM/AZ800U | 40 | 40 | 800×800×55 | 25 | 0.491 | 0.5-0.8 | 3365 | 4315×1320×1160 | 2.2 | 3380 |

| XM/AZ800U | 50 | 50 | 800×800×55 | 25 | 0.617 | 0.5-1 | 3915 | 4865×1320×1160 | 2.2 | 3090 |

| XM/AZ800U | 60 | 60 | 800×800×55 | 25 | 0.743 | 0.5-1 | 4465 | 5415×1320×1160 | 2.2 | 4070 |

| XM/AZ800U | 70 | 70 | 800×800×55 | 25 | 0.869 | 0.5-1.6 | 5015 | 5965×1320×1160 | 2.2 | 4360 |

| XM/AZ800U | 80 | 80 | 800×800×55 | 25 | 0.995 | 0.5-1.6 | 5565 | 6515×1320×1160 | 2.2 | 4700 |

| XM/AZ1000U | 100 | 62 | 1000×1000×60 | 30 | 1.48 | 0.5-1.6 | 5020 | 6110×1460×1360 | 3 | 6200 |

| XM/AZ1000U | 120 | 75 | 1000×1000×60 | 30 | 1.8 | 0.5-1.6 | 5800 | 6890×1460×1360 | 3 | 6710 |

| XM/AZ1250U | 150 | 58 | 1250×1250×65 | 30 | 2.26 | 0.5-1.6 | 5390 | 6920×1850×1620 | 3 | 11800 |

| XM/AZ1250U | 180 | 69 | 1250×1250×65 | 30 | 2.7 | 0.5-1.6 | 6100 | 7630×1850×1620 | 3 | 12700 |

| XM/AZ1250U | 200 | 79 | 1250×1250×65 | 30 | 3.02 | 0.5-1.6 | 6620 | 8150×1850×1620 | 3 | 13300 |

| XM/AZ1250U | 220 | 84 | 1250×1250×65 | 30 | 3.29 | 0.5-1.6 | 7080 | 8610×1850×1620 | 3 | 13900 |

| XM/AZ1250U | 250 | 95 | 1250×1250×65 | 30 | 3.73 | 0.5-1.6 | 7290 | 9320×1850×1620 | 3 | 14800 |

| XM/AZ1500U | 300 | 77 | 1500×1500×70 | 32 | 4.76 | 0.7-1.6 | 7450 | 9100×1960×1780 | 5.5 | 27000 |

| XM/AZ1500U | 320 | 83 | 1250×1250×65 | 32 | 5.14 | 0.7-1.6 | 7870 | 9520×1960×1780 | 5.5 | 27690 |

| XM/AZ1500U | 340 | 88 | 1250×1250×65 | 32 | 5.45 | 0.7-1.6 | 8220 | 9870×1960×1780 | 5.5 | 28380 |

| XM/AZ1500U | 350 | 90 | 1500×1500×70 | 32 | 5.58 | 0.7-1.6 | 8360 | 10010×1960×1780 | 5.5 | 28730 |

| XM/AZ1500U | 380 | 98 | 1500×1500×70 | 32 | 6.08 | 0.7-1.6 | 8920 | 10570×1960×1780 | 5.5 | 29760 |

| XM/AZ1500U | 400 | 103 | 1500×1500×70 | 32 | 6.39 | 0.7-1.6 | 9270 | 10920×1960×1780 | 5.5 | 30450 |

| XM/AZ1500U | 450 | 116 | 1500×1500×70 | 32 | 7.21 | 0.7-1.6 | 10180 | 11830×1960×1780 | 5.5 | 32170 |

| XM/AZ1500U | 500 | 128 | 1500×1500×70 | 32 | 7.96 | 0.7-1.6 | 11020 | 12670×1960×1780 | 5.5 | 33890 |

Links:https://www.globefindpro.com/products/55544.html

-

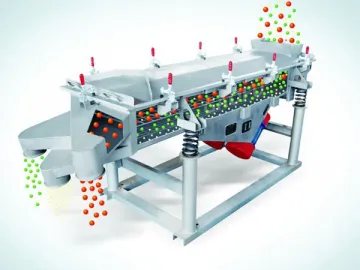

Linear Vibrating Screen

Linear Vibrating Screen

-

Intermittent Ball Mill

Intermittent Ball Mill

-

Drum Screen

Drum Screen

-

Cement Rotary Kiln

Cement Rotary Kiln

-

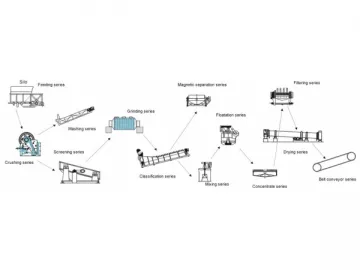

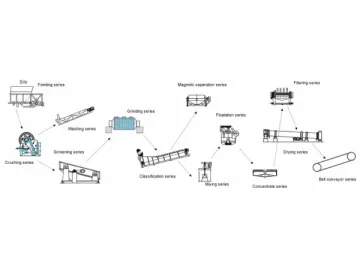

Copper-Lead-Zinc Separation Line

Copper-Lead-Zinc Separation Line

-

Active Lime Rotary Kiln

Active Lime Rotary Kiln

-

Hematite Separation Line

Hematite Separation Line

-

High Frequency Screen

High Frequency Screen

-

Dry Magnetic Separator

Dry Magnetic Separator

-

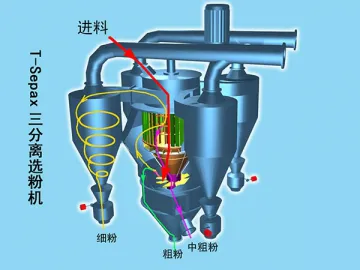

High Efficiency Cyclone Separator (for Powder)

High Efficiency Cyclone Separator (for Powder)

-

Air Swept Ball Mill

Air Swept Ball Mill

-

Gold Gravity Separation Line

Gold Gravity Separation Line